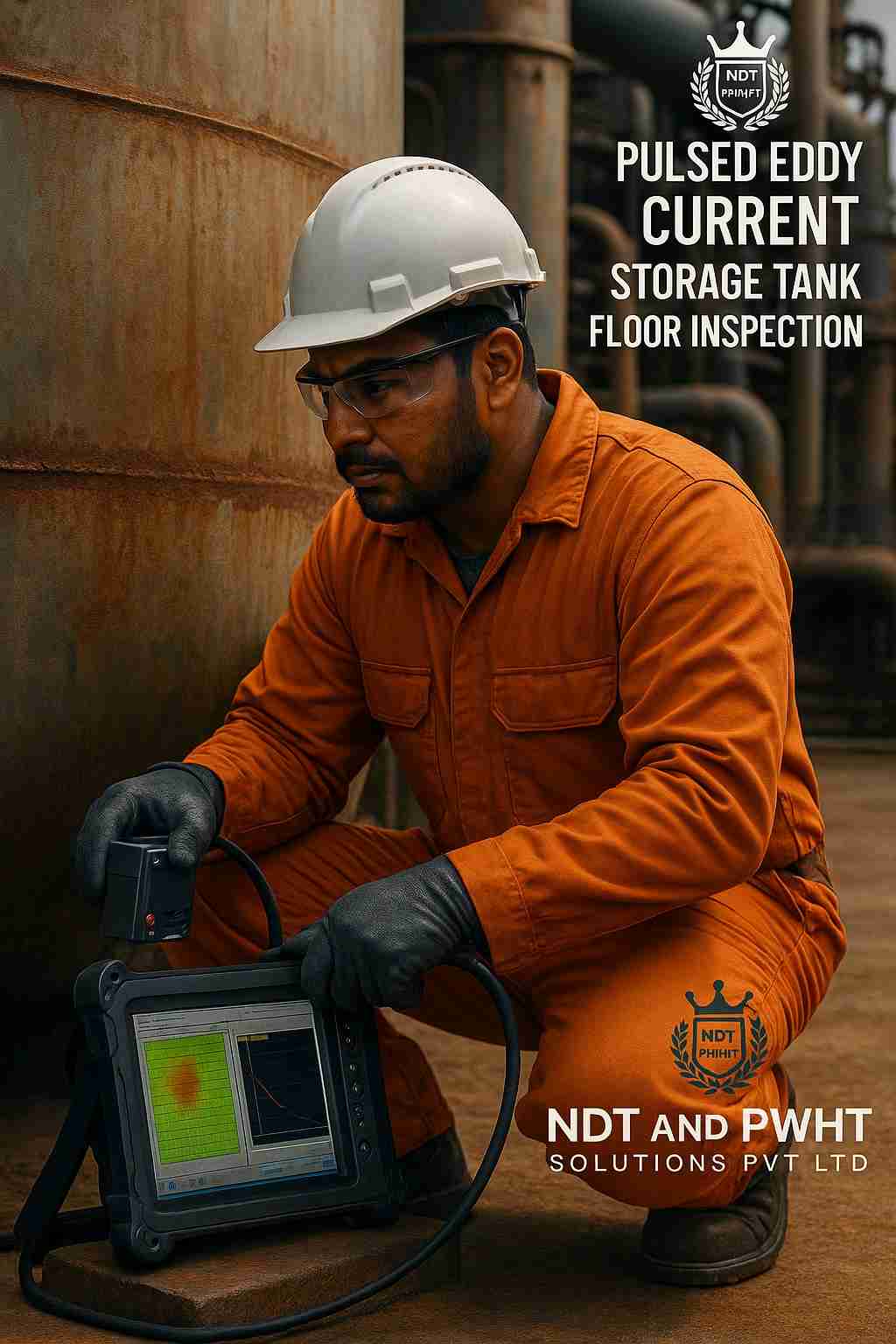

Storage Tanks Floor Inspection

Pulse Eddy Current (PEC) Inspection for Storage Tank Floor Mapping by NDT AND PWHT SOLUTIONS PVT LTD – Global NDT Service Provider Pulse Eddy Current (PEC) technology is a powerful Non-Destructive Testing (NDT) solution for evaluating the condition of storage tank floors, especially while the tanks are in service and full of product. This inspection method allows fast, accurate detection of corrosion, wall thinning, and internal floor degradation without opening the tank or interrupting operations.

At NDT AND PWHT SOLUTIONS PVT LTD, we specialize in floor mapping inspections using PEC, providing asset owners and operators with actionable insights to support preventive maintenance, optimize repair schedules, and enhance operational safety.

Why Storage Tank Floor Inspection Matters?

Tank floors are exposed to long-term corrosion due to water, sludge, chemicals, and microbial activity. Undetected corrosion can result in leaks, environmental hazards, and costly unplanned outages. Conventional inspection often requires draining, cleaning, and confined space entry—costly and time-intensive steps that may not be feasible during continuous operations.

With PEC, tank floors can be inspected externally, through the shell or annular ring, and without removing insulation or fireproofing—enabling efficient, real-time corrosion monitoring while tanks remain online.

Key Applications:

In-service aboveground storage tanks (ASTs)

Annular rings and tank floor edge mapping

Tank shell-to-bottom welds

Insulated tank floors

Petrochemical and fuel storage tanks

Chemical, water, and waste storage facilities

Technical Capabilities:

Inspection Through: Coatings, liners, insulation, or concrete pads

Material Compatibility: Carbon steel

Detection: General corrosion, wall thinning, and corrosion profiles

Tank Access: No need for emptying or internal access

Surface Prep: Minimal surface preparation required

Support: RBI planning and floor integrity assessment.

Benefits of PEC for Tank Floor Mapping:

Online inspection – No need to empty tanks

Safe & contactless – No confined space entry

High productivity – Large areas covered quickly

Accurate mapping – Remaining wall thickness estimation

Minimal disruption – Inspections during full operation

Cost-saving – Reduces downtime and repair costs.

Global Service Readiness

NDT AND PWHT SOLUTIONS PVT LTD brings extensive experience in PEC-based tank floor inspection across critical industries like oil & gas, chemicals, terminals, refineries, and utilities. Our team is fully trained, certified, and equipped to mobilize worldwide.

We provide data-rich corrosion maps, enabling smart decisions, RBI compliance, and asset life extension, all with minimal disruption to your operations.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌍 Operating Worldwide

📧 support@solutionss.org

Pulse Eddy Current Inspection – Corrosion Under Insulation (CUI) – Ready to Deploy.