With over a decade of field experience and global service capability.

8

YEARS OF EXPRIENCE

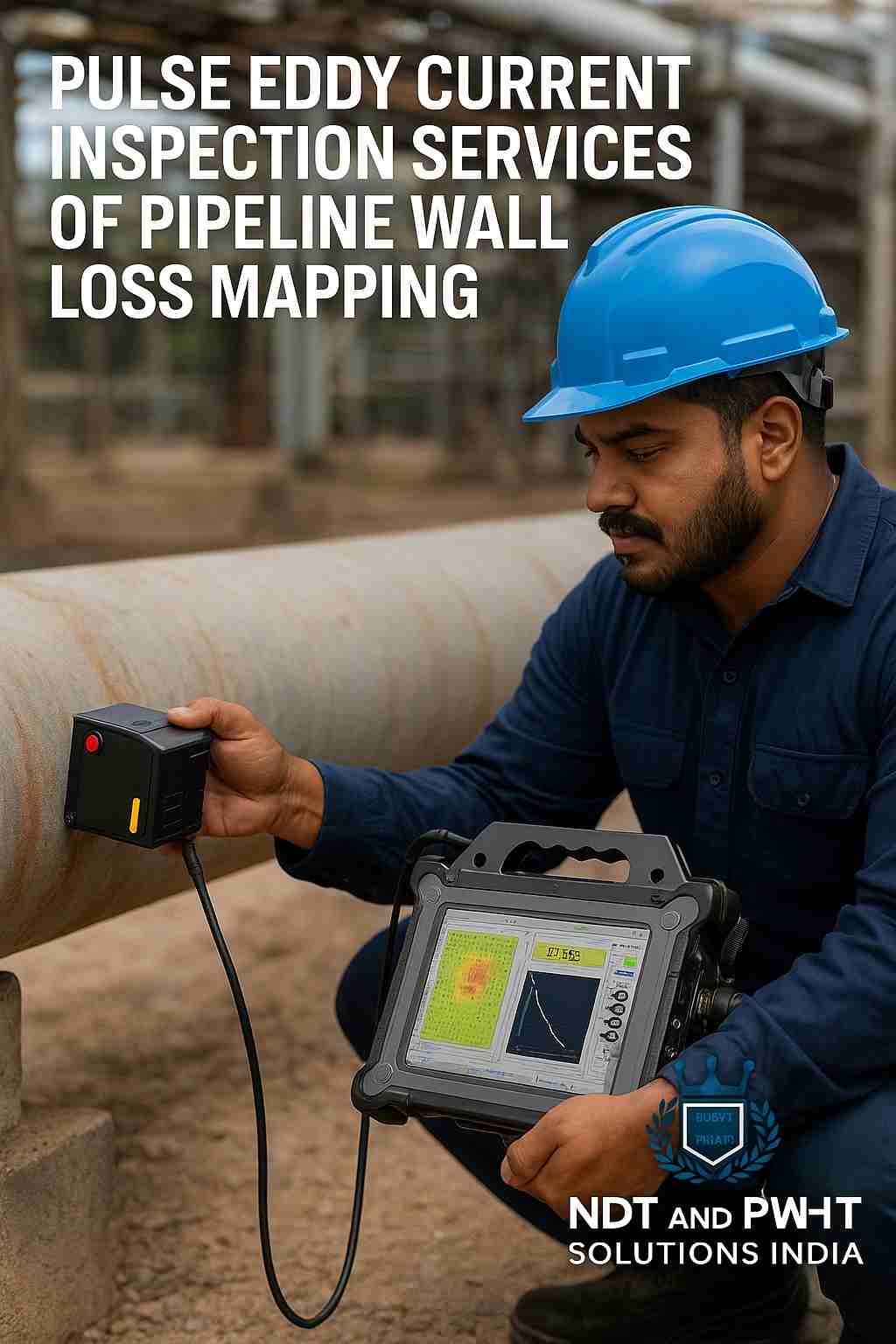

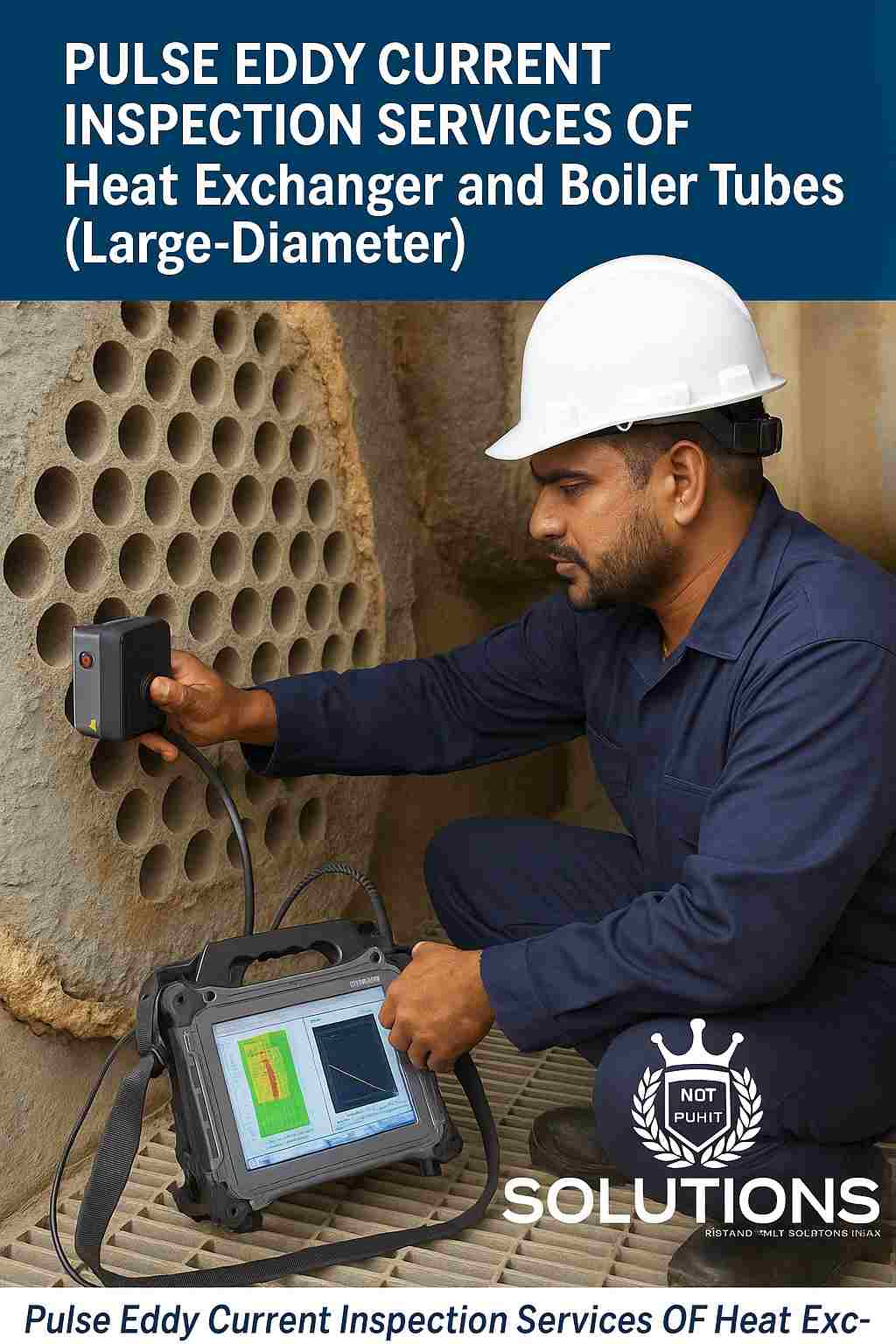

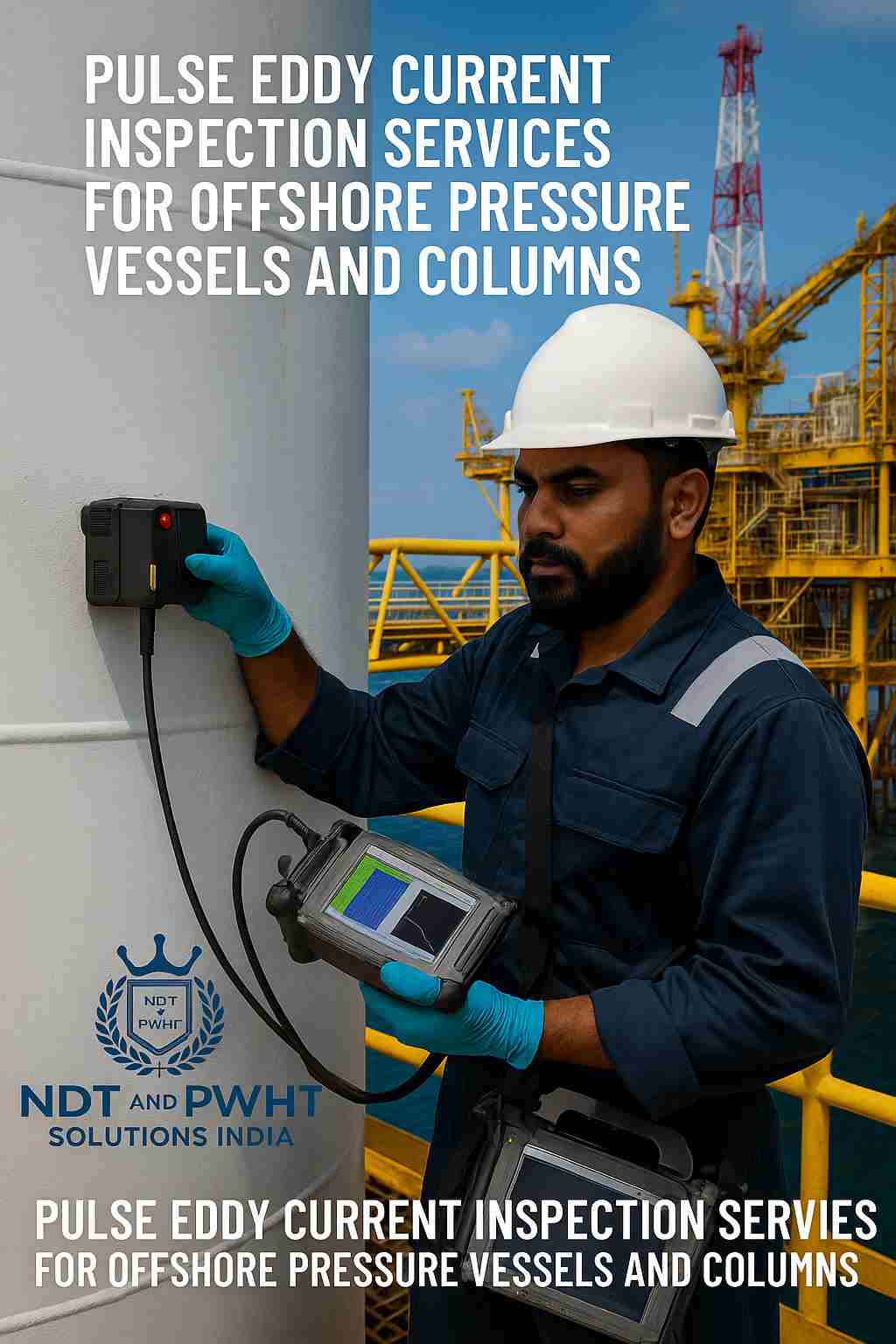

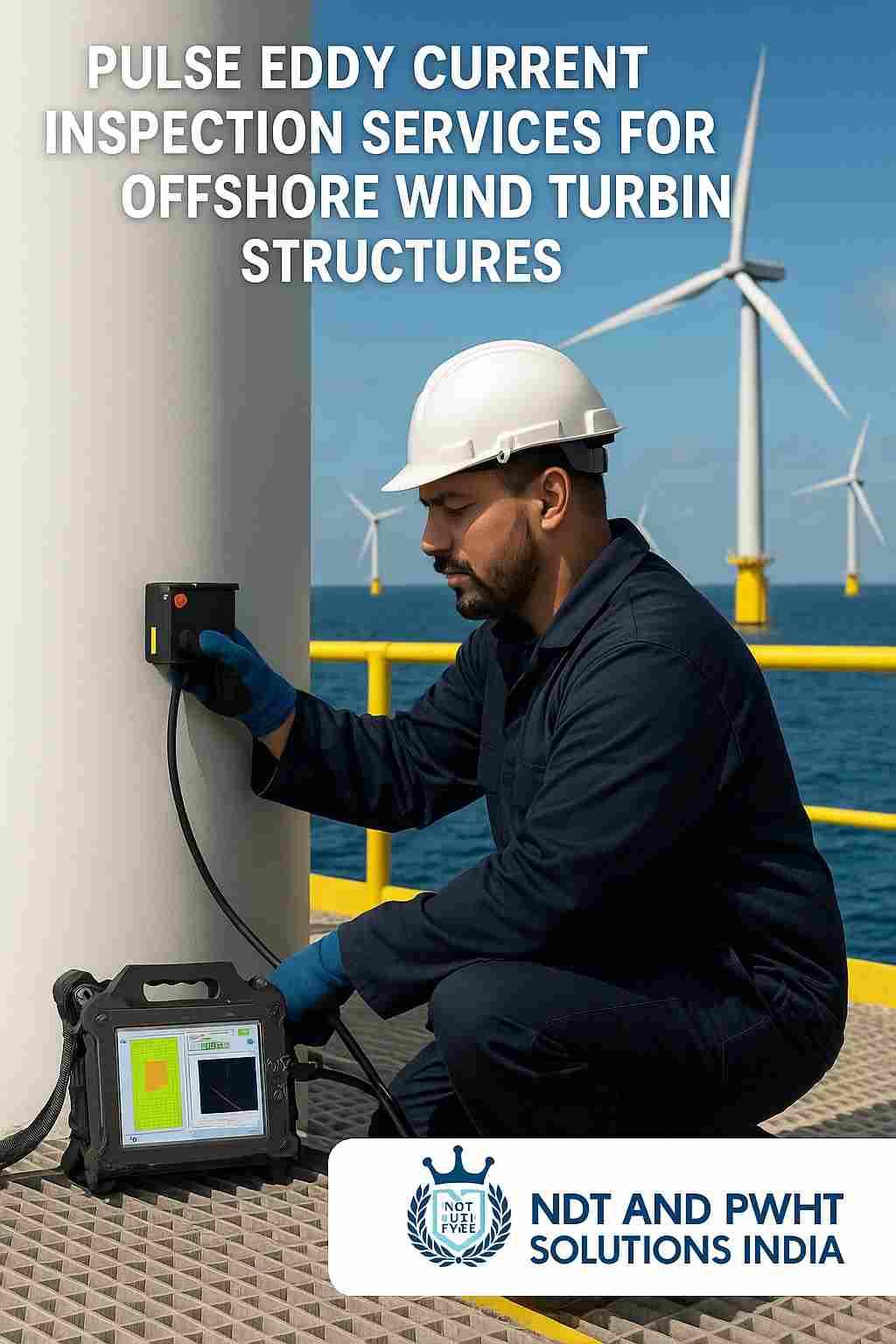

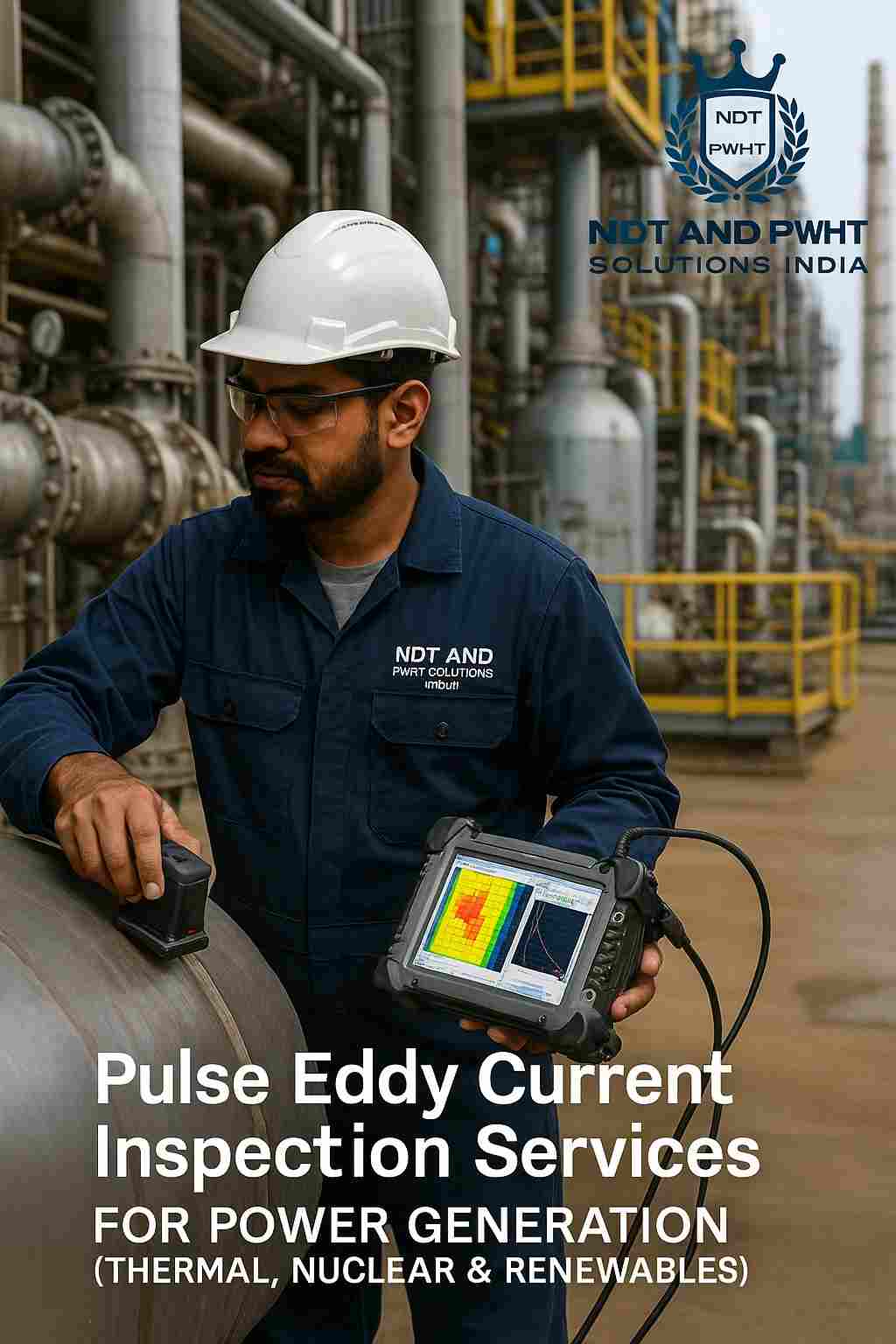

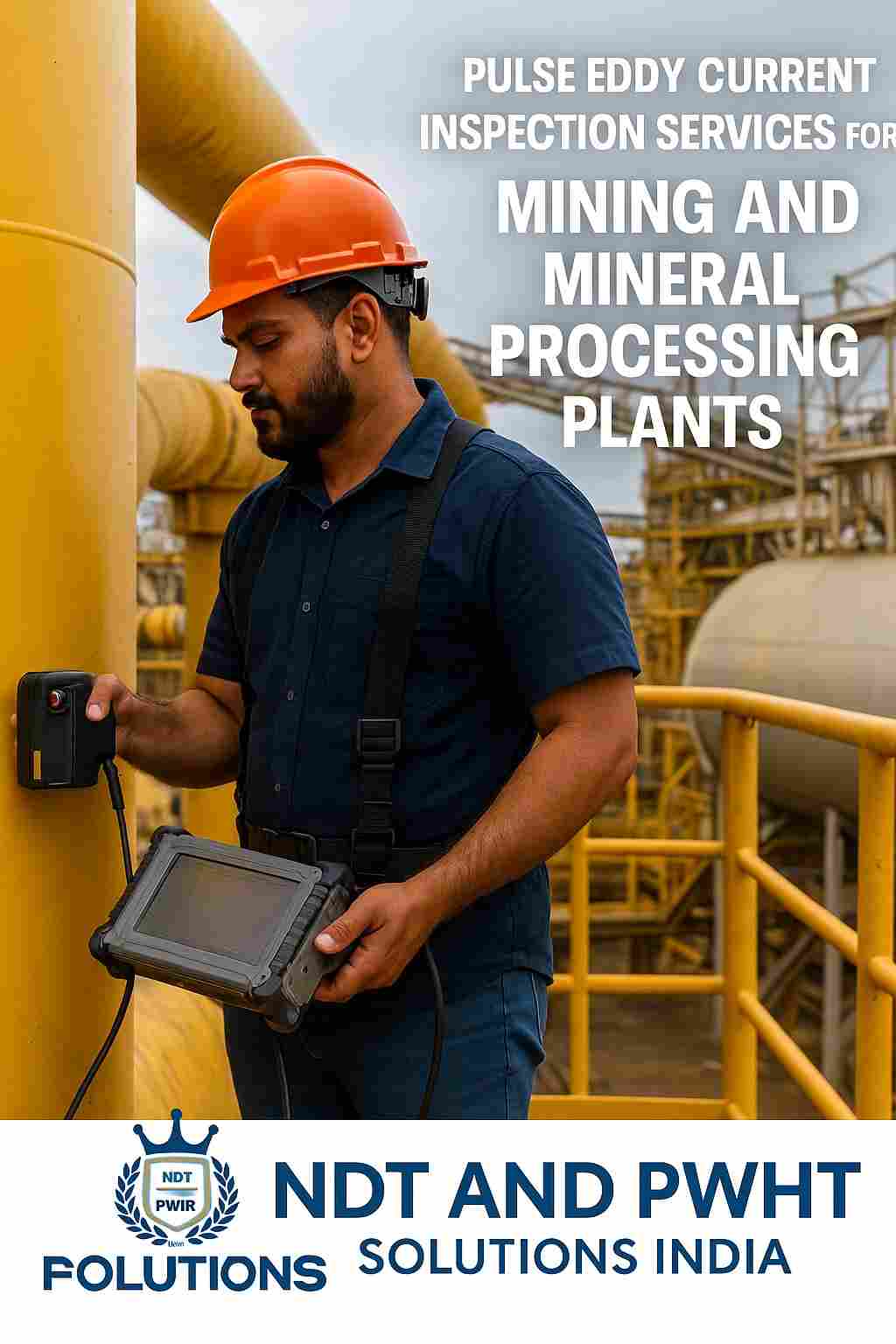

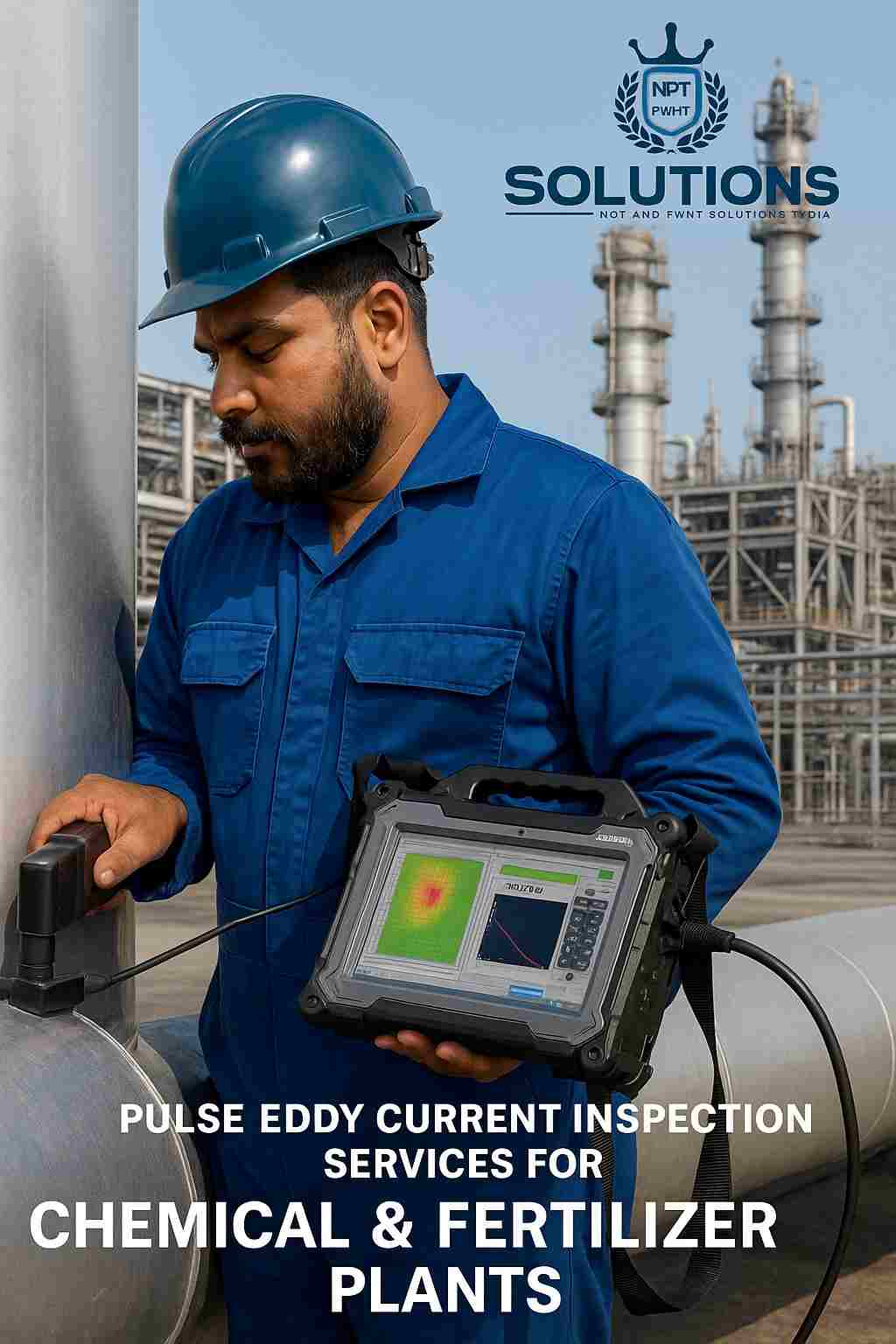

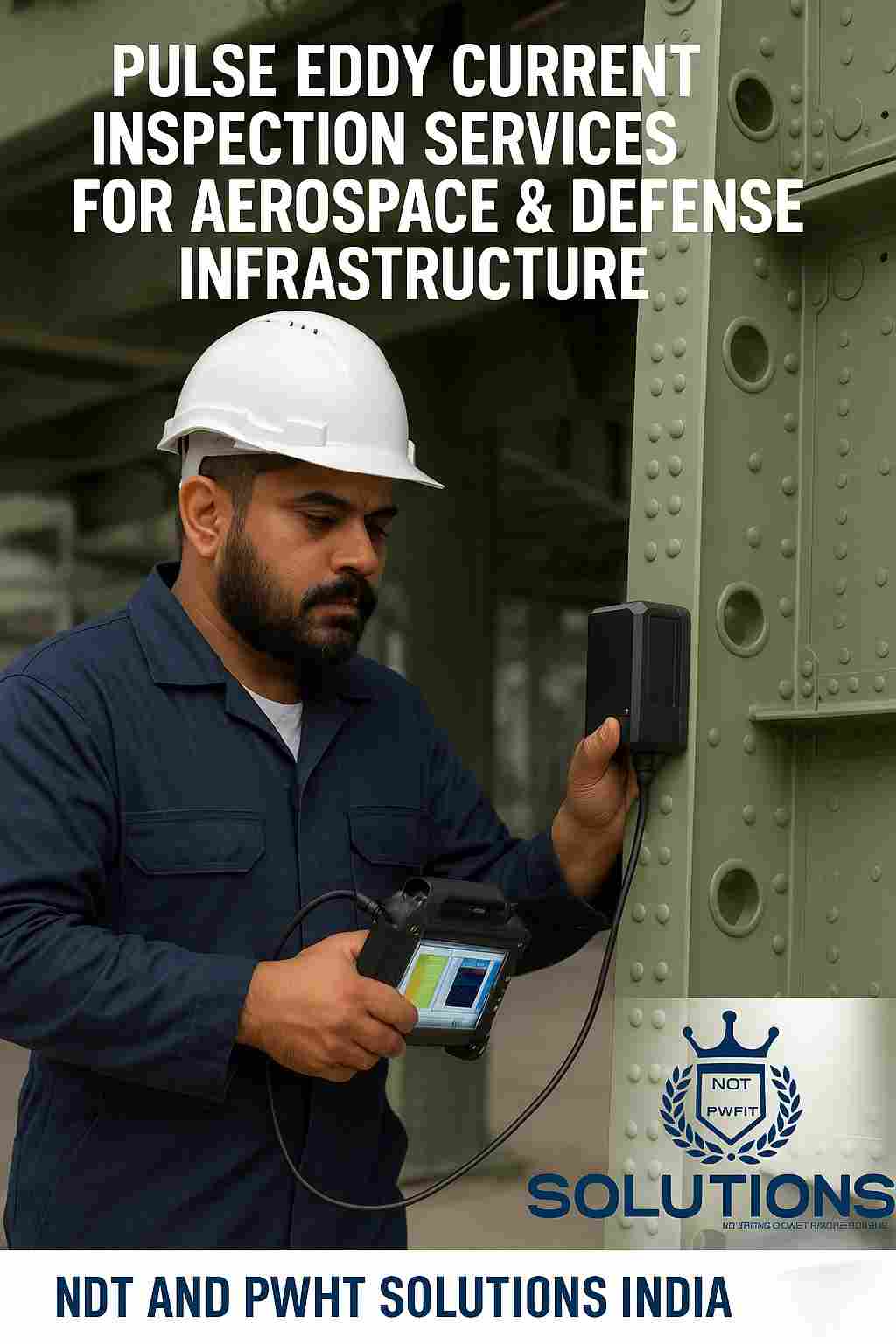

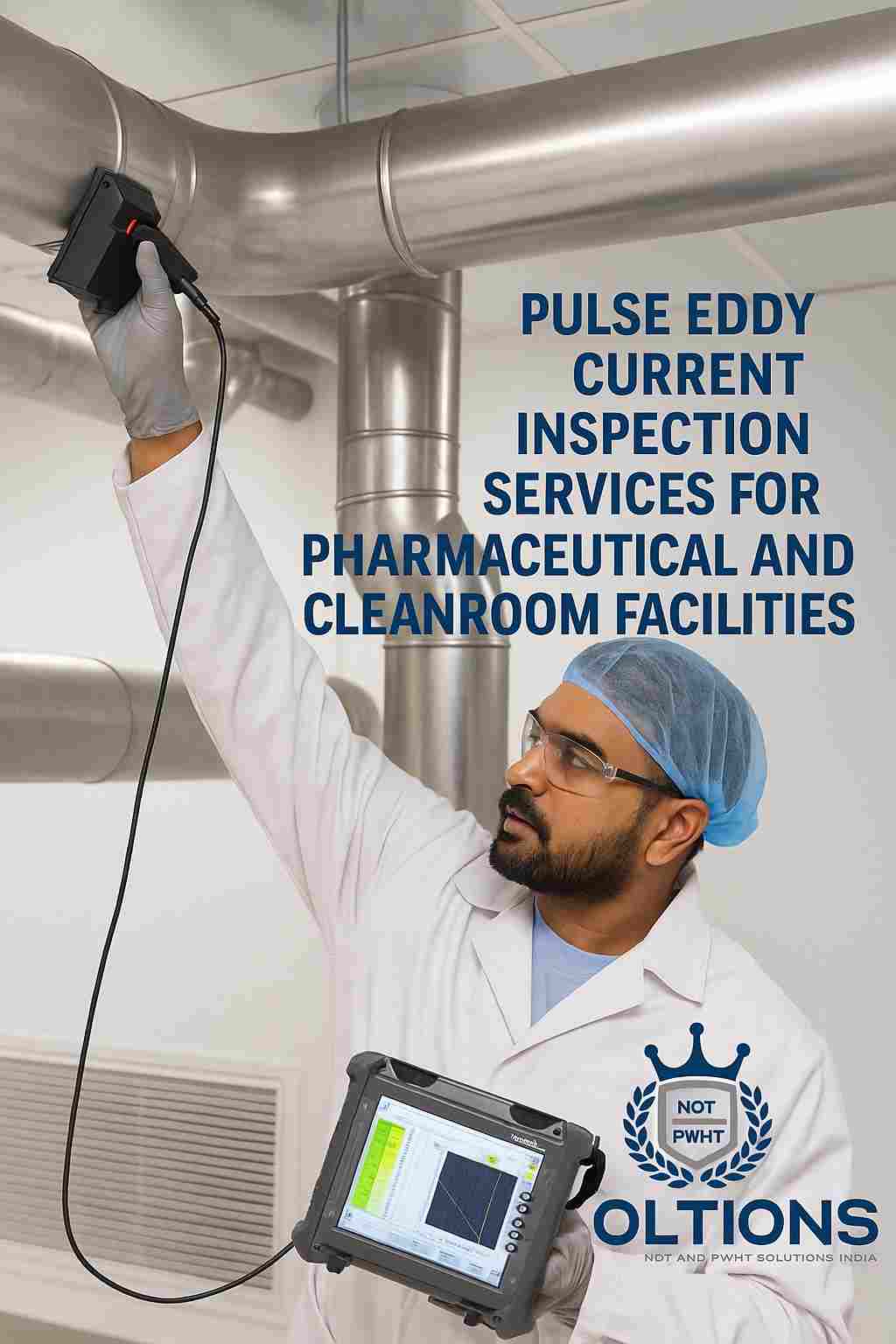

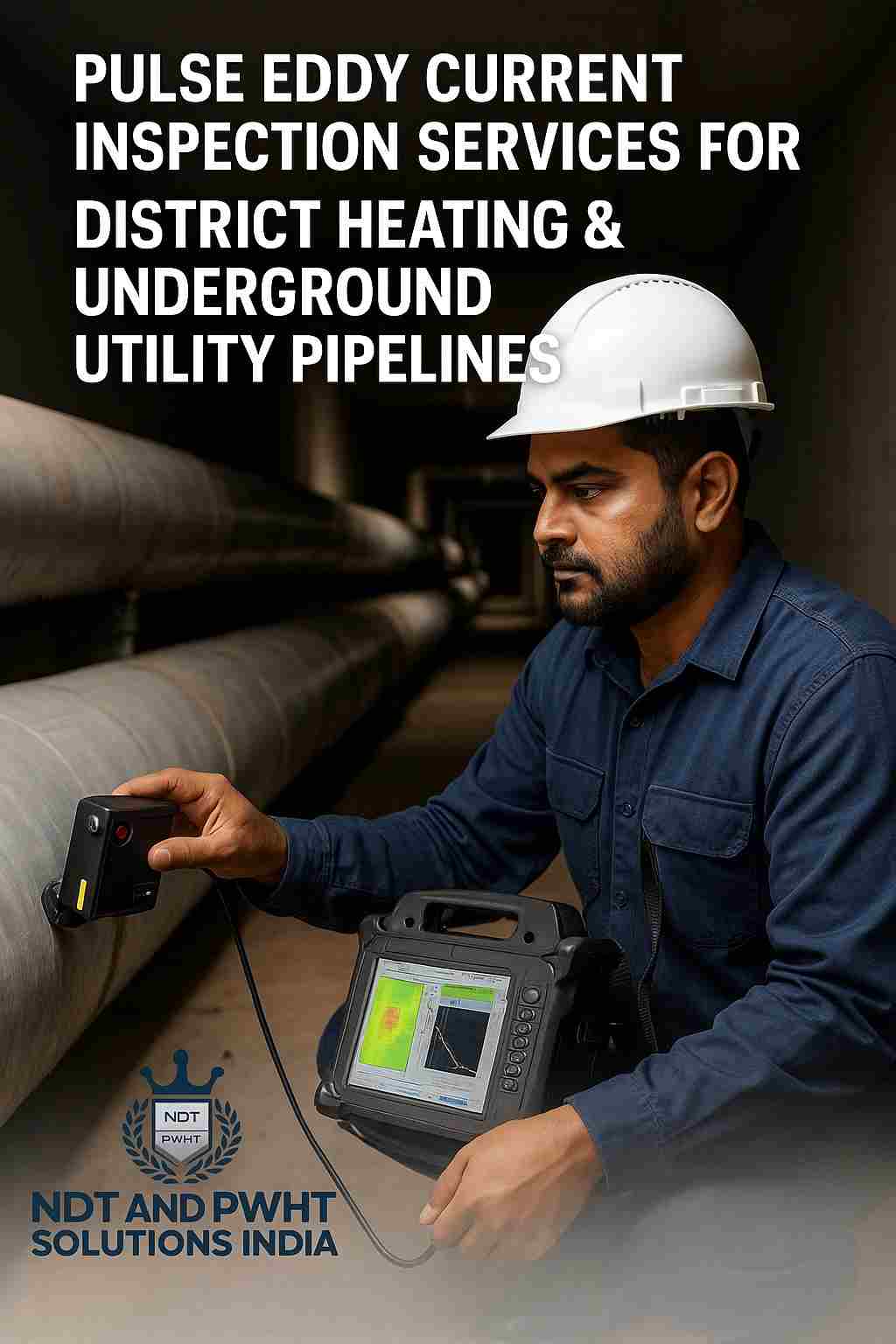

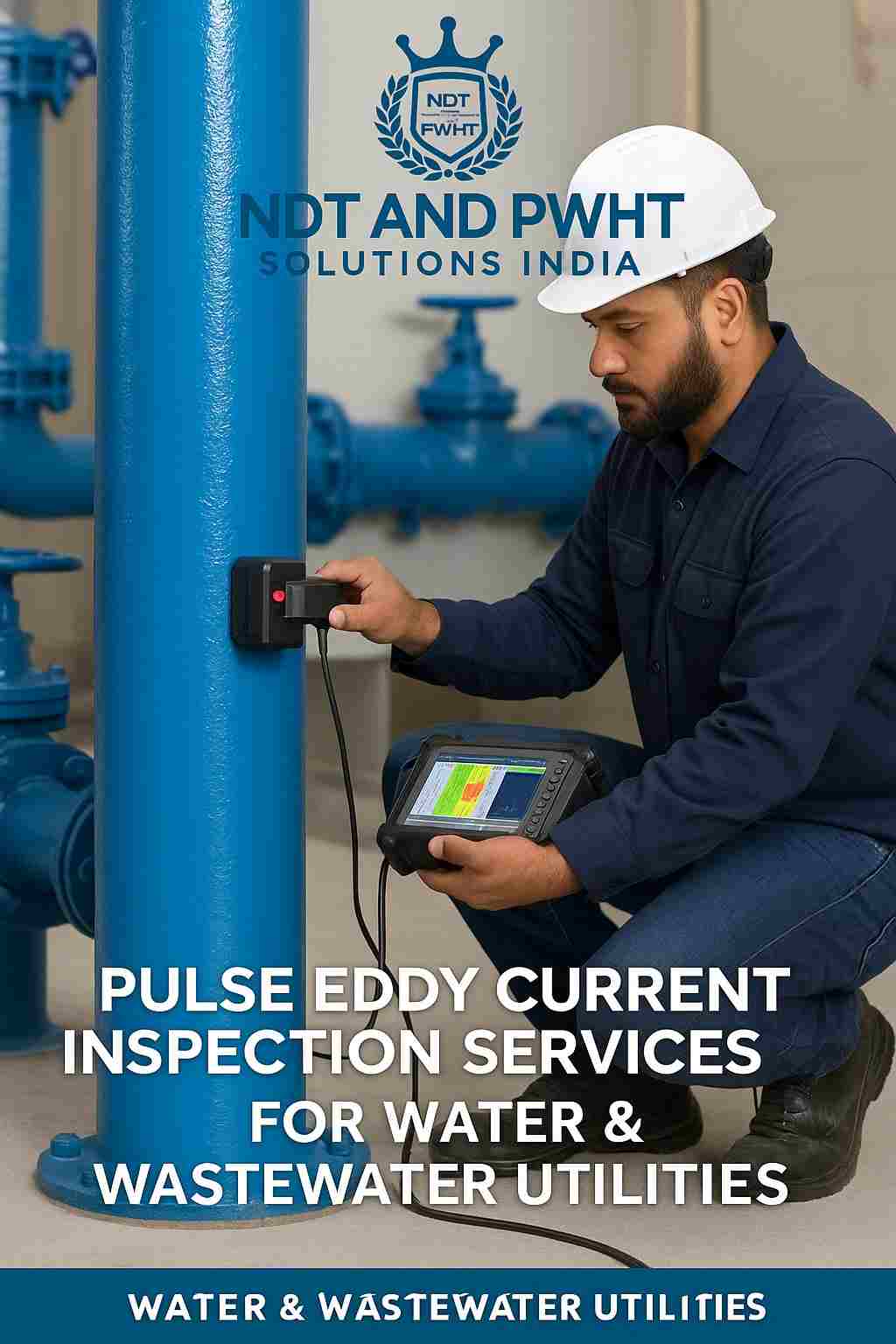

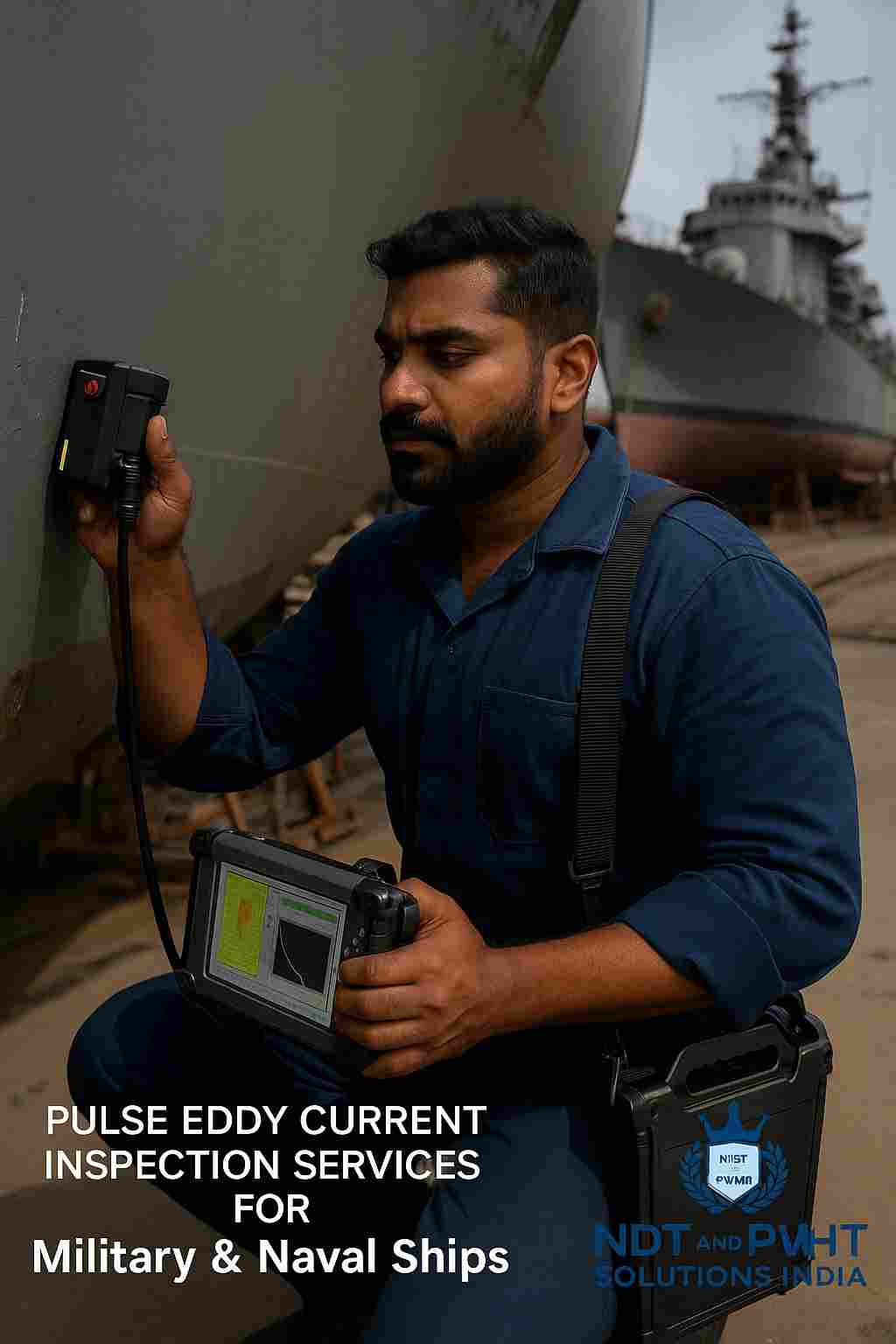

At NDT and PWHT Solutions Pvt Ltd, we are proud to offer advanced Pulsed Eddy Current (PEC) Testing services, enabling fast, accurate, and non-intrusive detection of corrosion and wall thinning beneath insulation, coatings, and fireproofing materials.PEC is a game-changing solution for asset owners in oil & gas, petrochemical, marine, offshore, and power sectors-allowing in-service inspection without the need for insulation stripping or process interruption.

ABOUT USPrecision Corrosion Monitoring with PEC & PECA Technology

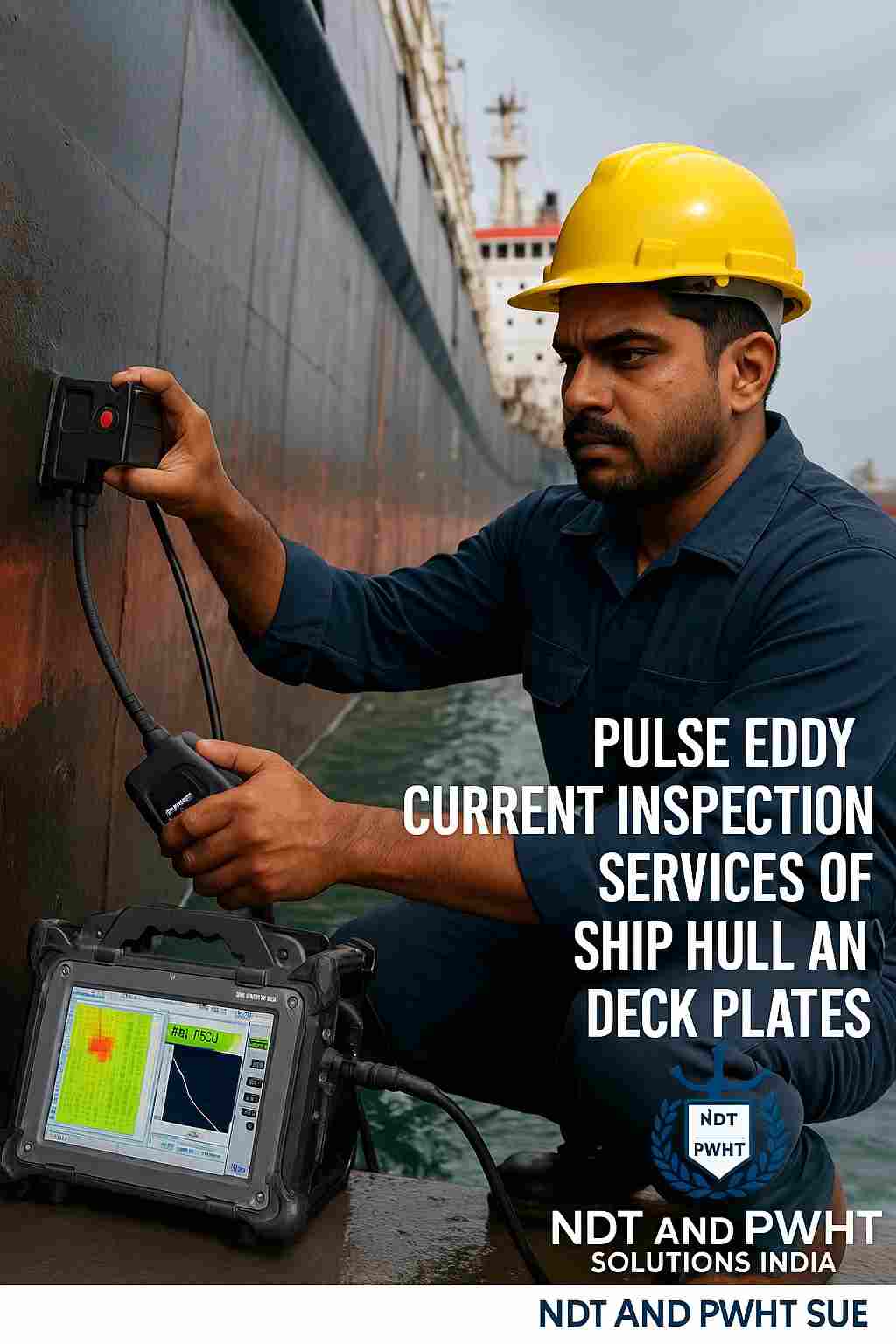

Powered by NDT AND PWHT SOLUTIONS PVT LTD – India | Serving Globally Looking for a non-intrusive, in-service solution to detect corrosion under insulation or coatings? We specialize in Pulse Eddy Current (PEC) and Pulse Eddy Current Array (PECA) inspection services designed to accurately detect wall loss through insulation, coatings, marine layers, and fireproofing materials without the need for shutdowns or surface prep. Our solutions are ideal for:

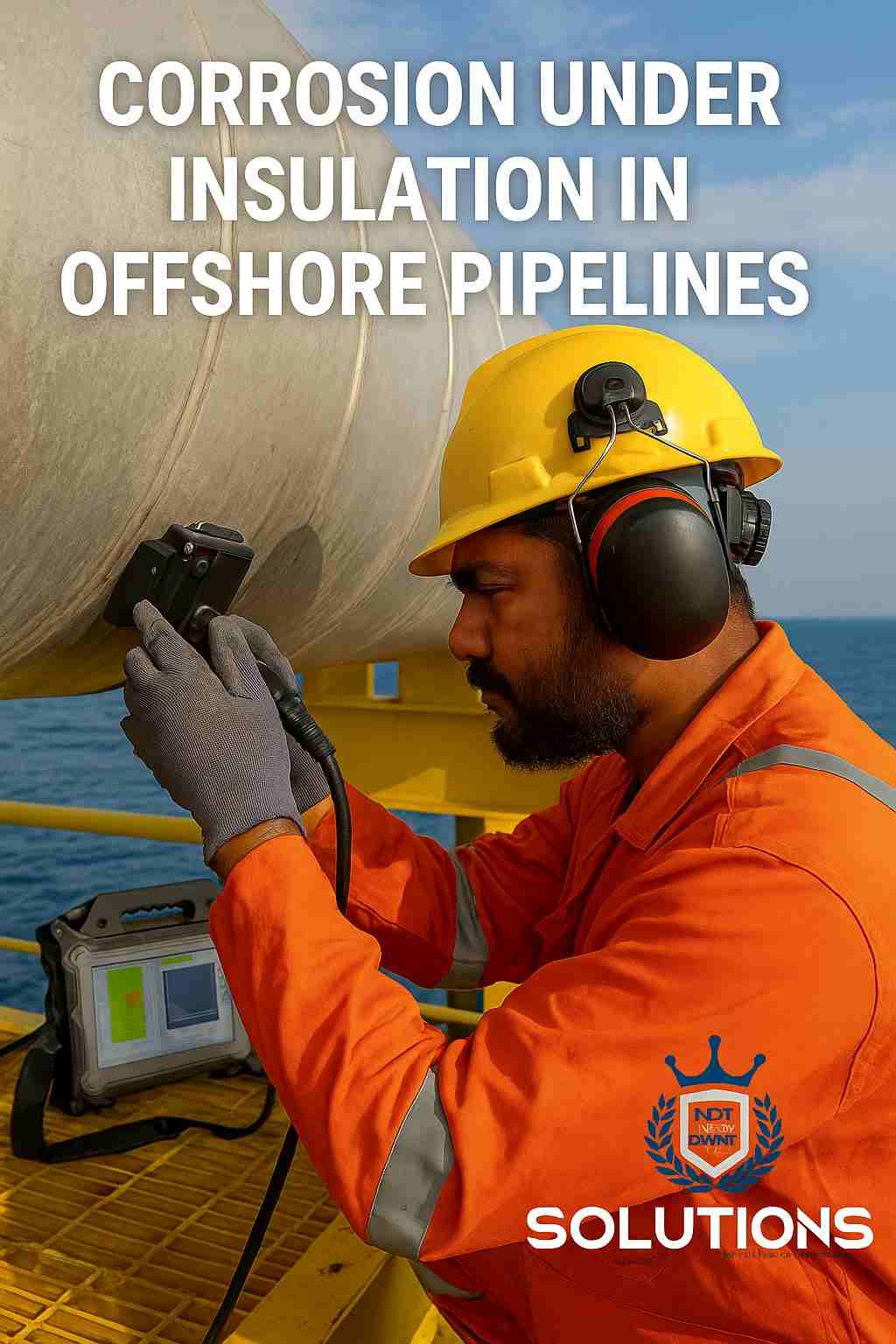

- Corrosion Under Insulation (CUI)

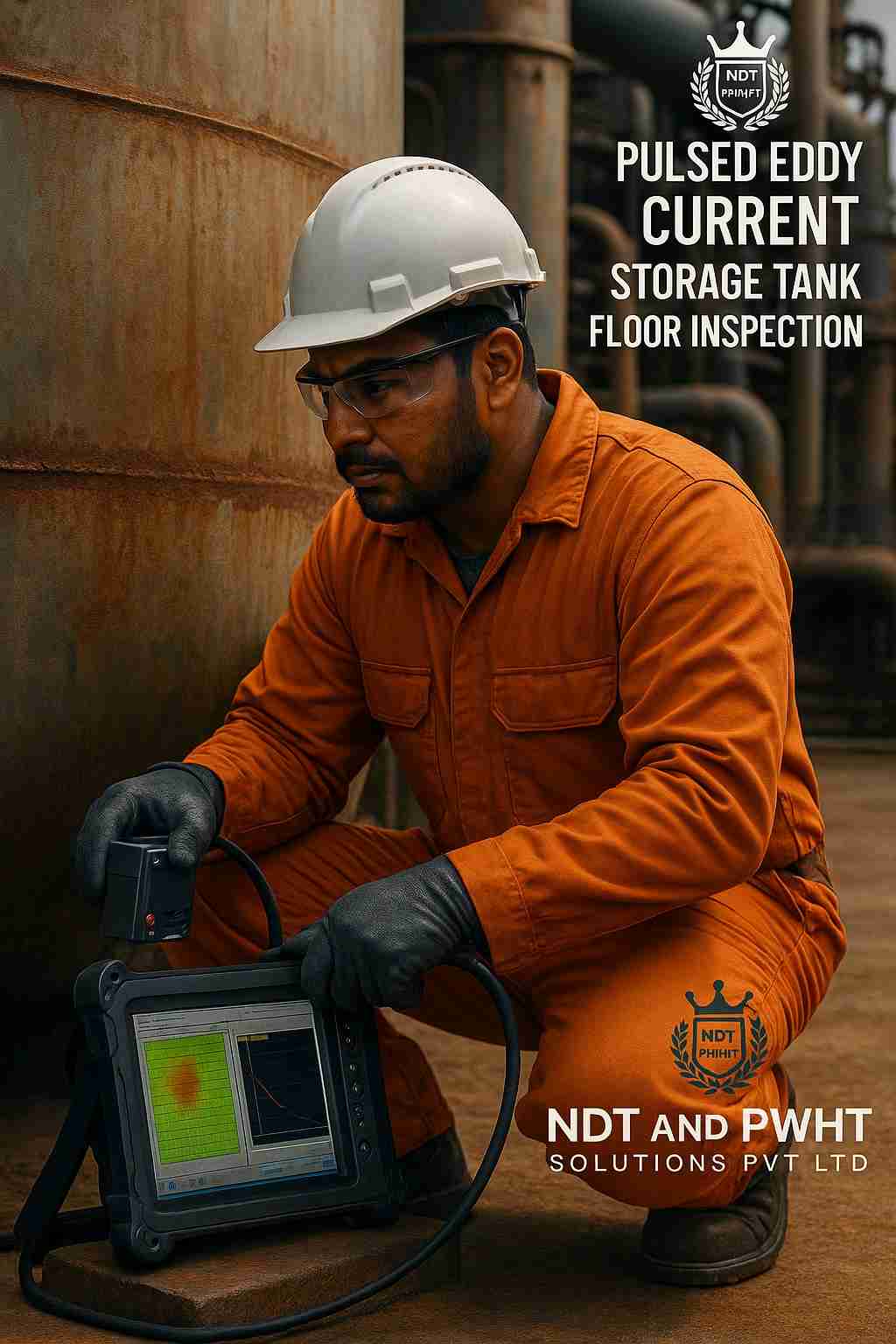

- Tank floor mapping

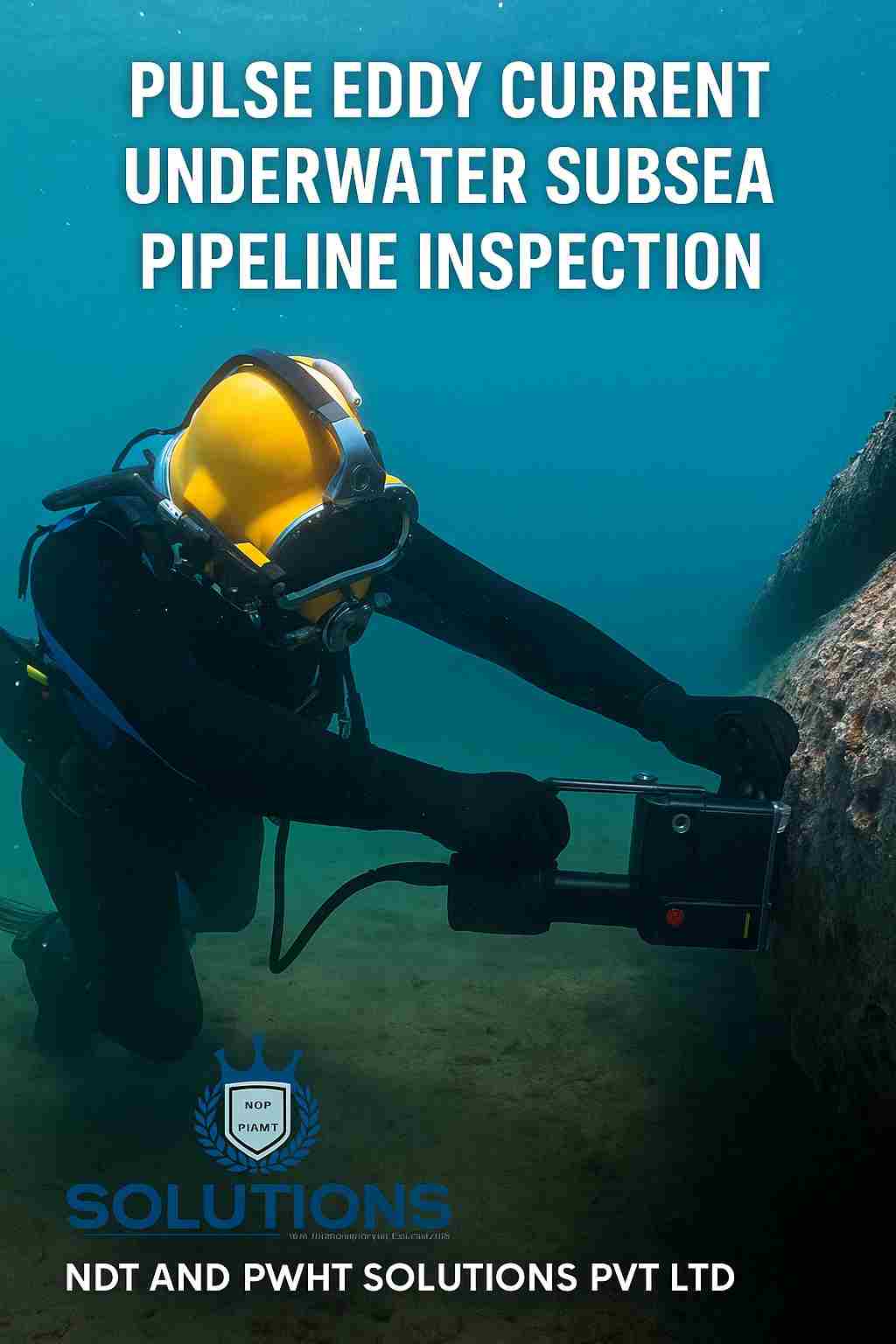

- Offshore & subsea structures

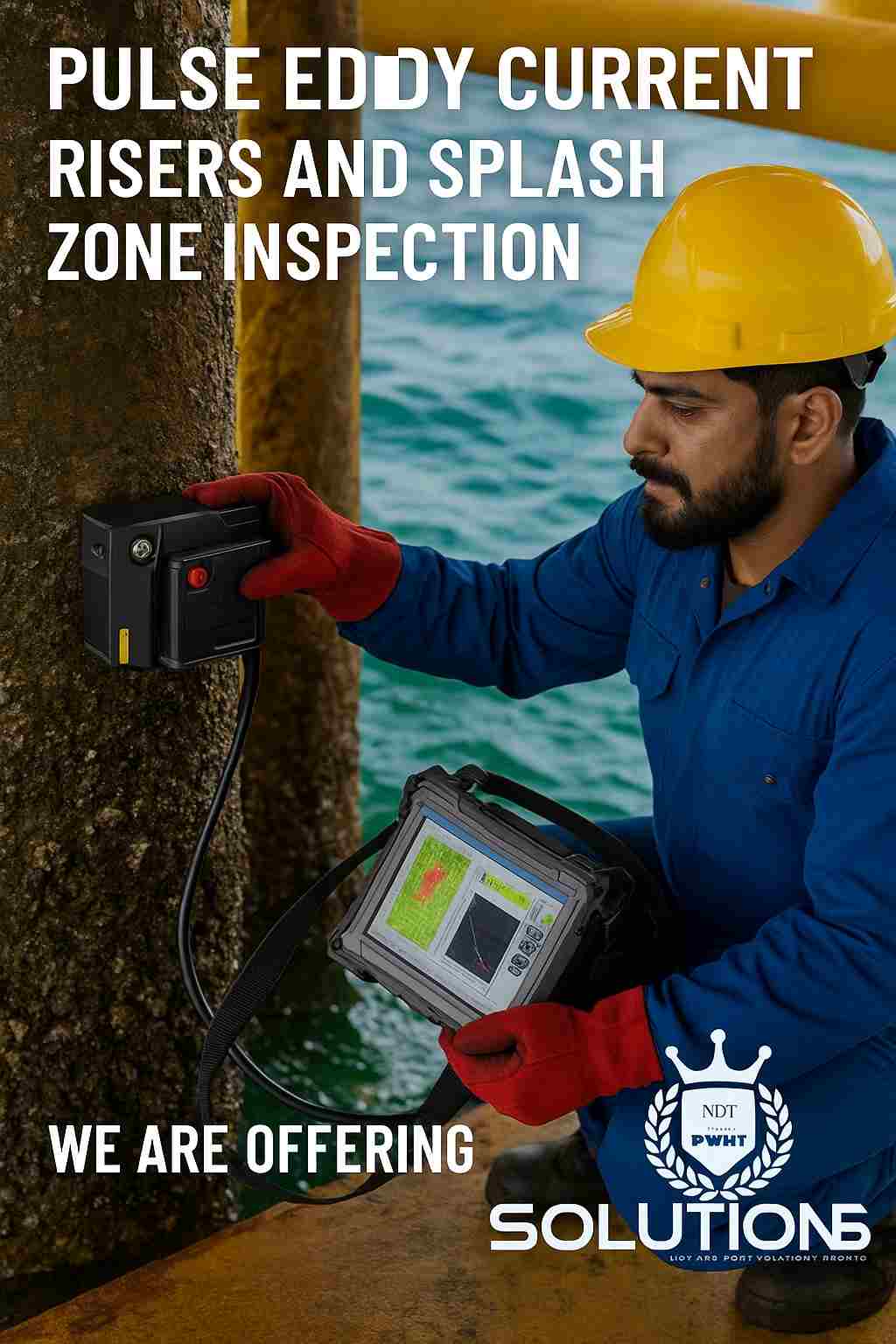

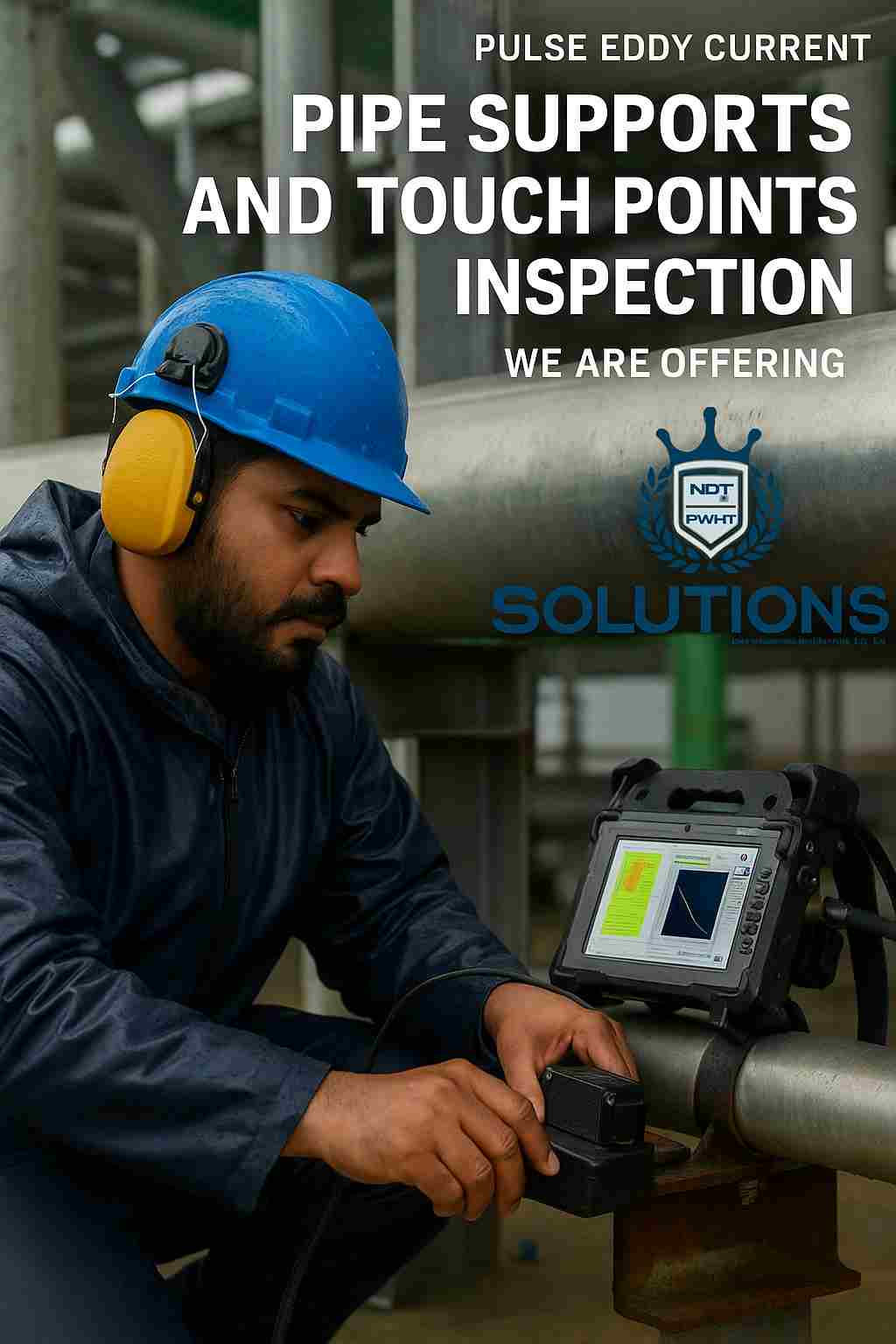

- Pipe supports, splash zones & touch points

- Power plants, chemical facilities, and ship hulls.

Our Expertise & Offerings

Assets We Support With PEC Technology!

Meet our Experts Crew

The Team That Makes It Happen

Adavan Naveen

Our Senior PEC Technologist Mr. Adavan Naveen Kumar brings extensive field expertise and leadership in advanced Pulse Eddy Current (PEC) inspection across critical industries including oil & gas, marine, offshore, and power generation.

Surya Raja

Our PEC Technologist & Project Manager Mr.Raja is a dynamic Pulse Eddy Current (PEC) technologist and experienced Project Manager, known for delivering precision-driven inspection solutions while effectively managing field operations.

Saravanan

Our PEC Technologist Mr.Saravanan ASNT & PCN NDT Level III Certified Mr.Saravanan is a highly skilled Pulse Eddy Current (PEC) technologist and a certified NDT Level III expert (ASNT & PCN) with deep technical knowledge and a hands-on approach to field inspection.

Selva Kumar

ASNT NDT Level III Certified Mr.Selva Kumar is a dedicated Pulse Eddy Current (PEC) technologist and a certified ASNT NDT Level III professional with a strong background in advanced non-destructive testing and field operations.

Rakesh Swain

Our PEC Technologist & Operations Manager Mr.Rakesh Swain serves as a key pillar in our PEC operations, combining deep technical expertise in Pulse Eddy Current (PEC) inspections with strong leadership as our Operations Manager.

Mr. Rajesh Kumar Padhiary

Our PEC Technologist & Operations Manager Mr. Rajesh Kumar Padhiary is a highly experienced Pulse Eddy Current (PEC) technologist and serves as the Operations Manager, With a strong foundation in non-destructive testing and a focus on operational excellence, he plays a key role in delivering high-quality inspection outcomes across industrial sectors.

Advanced Pulse Eddy Current Solutions with more quality

NDT & PWHT Solutions

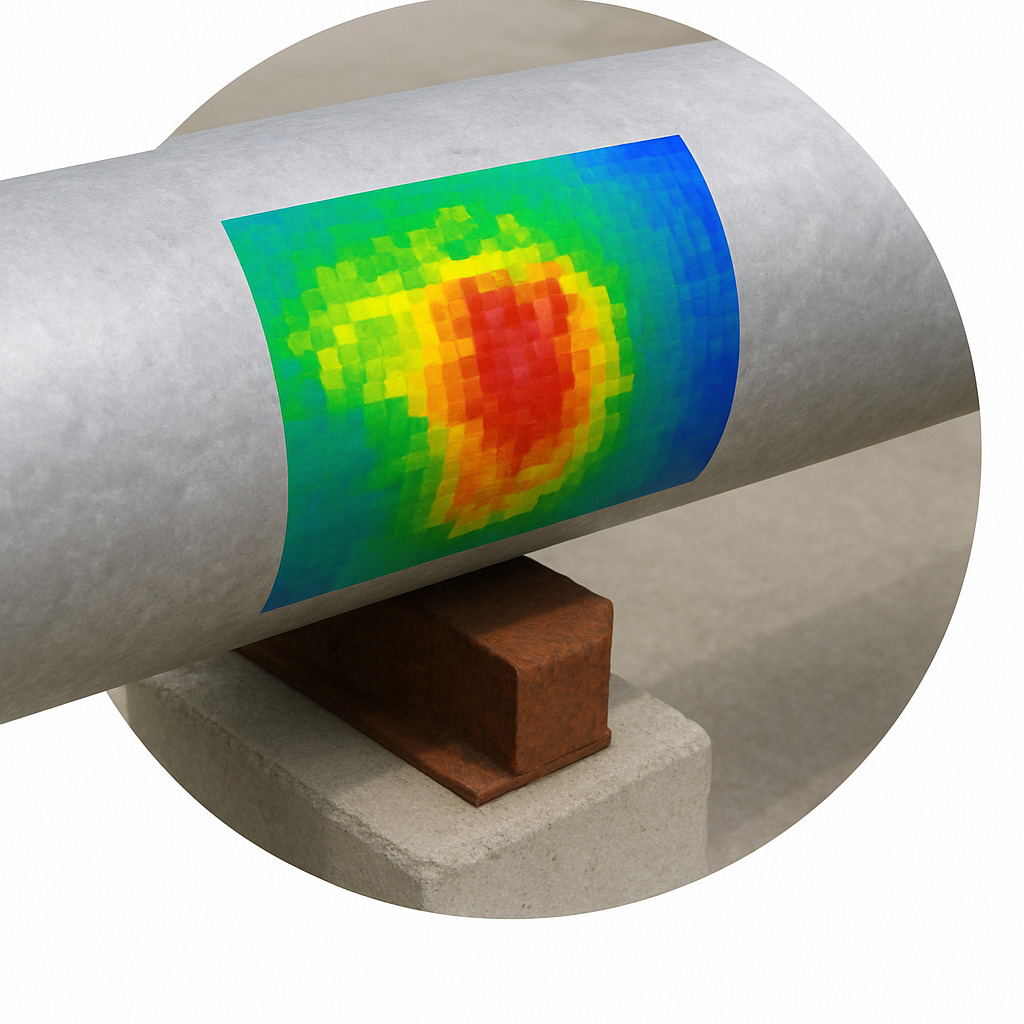

At NDT & PWHT Solutions, our PEC systems detect wall loss through insulation up to 100mm thick—without shutdown. Trusted in over 500+ site inspections, we combine high-resolution probes with multiplexing tech for faster, data-driven corrosion monitoring.

ABOUT USPulse Eddy Current for Underwater Inspection

Pulse Eddy Current technology enables accurate, non-contact wall thickness measurements even below the waterline. Ideal for subsea risers, caissons, splash zones, and offshore structures, PEC performs through marine growth, coatings, and corrosion layers eliminating the need for surface prep or dry docking.

Pulse Eddy Current for High-Temperature

Our PEC systems are engineered to operate on surfaces up to 500°C (932°F) without requiring plant shutdown. Perfect for live pipelines, heater coils, furnaces, and hot vessels, PEC offers real-time thickness data without interrupting process flow.

Pulse Eddy Current for Corrosion Under Insulation (CUI)

PEC can accurately measure wall thickness through insulation up to 500 mm , including metal cladding, weatherproofing, fireproofing, and various coating layers. This makes it ideal for inspecting insulated pipelines, vessels, elbows, and bends all while the system remains in service.