Risers and Splash Zone Inspection

Risers and Splash Zone Inspection

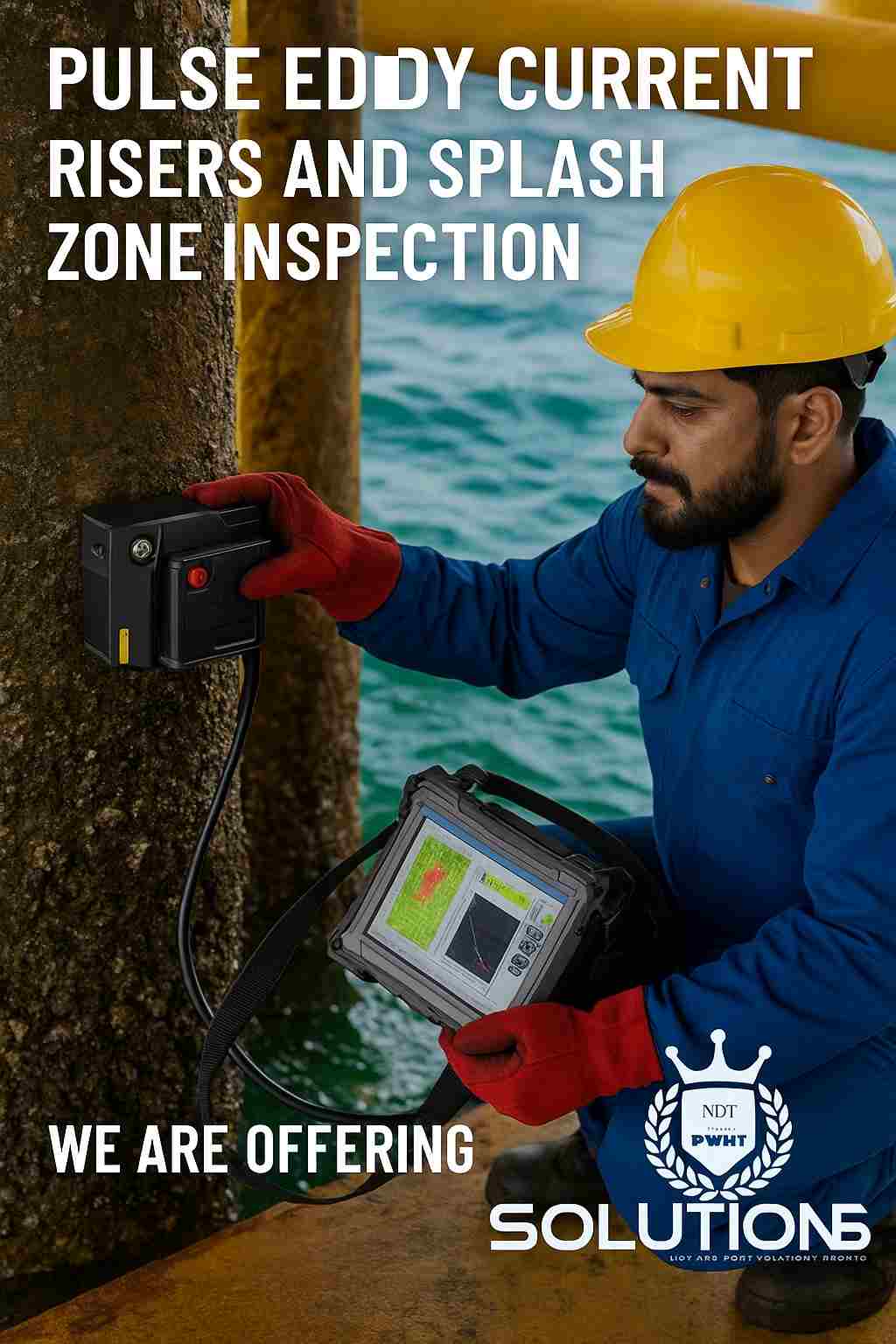

Pulse Eddy Current (PEC) Inspection for Risers and Splash Zone Areas by NDT AND PWHT SOLUTIONS PVT LTD – Global Service Provider in Advanced NDT Solutions Pulse Eddy Current (PEC) technology offers a safe, efficient, and non-intrusive solution to detect corrosion and wall loss in risers and splash zone areas, which are among the most critical and corrosion-prone zones in offshore structures.

At NDT AND PWHT SOLUTIONS PVT LTD, we deliver specialized PEC inspection services for these challenging environments—without removing insulation, coatings, or marine growth, and without interrupting operations.

Why Inspect Risers and Splash Zones?

Risers and splash zones are constantly exposed to cyclic immersion, wave impact, and oxygenated seawater, making them highly susceptible to corrosion under coatings, fireproofing, or marine growth. Traditional inspection methods often require scaffolding, coating removal, or shutdowns, increasing safety risks and operational downtime.

With PEC, we provide accurate wall thickness measurements through these barriers, delivering fast and safe integrity data even in difficult-to-access offshore areas.

Key Applications

Offshore platform risers and conductors

Splash zone areas of jackets and legs

Subsea spools and riser clamps

Fireproofed riser supports and guides

Touchpoints and welded joints in marine environments

Technical Highlights

Works through: Marine growth, coatings, insulation, and fireproofing

Material compatibility: Ferromagnetic (e.g., carbon steel)

Wall thickness range: Up to 100 mm

Access requirements: Surface contact only; no cleaning or removal needed

Output: Real-time wall loss estimation and corrosion profiling.

Key Benefits

No insulation or coating removal

Safe for live offshore structures – No shutdown required

Reduces diving & rope access time

Faster inspection cycles – Ideal for wide coverage

Minimizes risk – Non-contact and operator-safe

Supports RBI and integrity programs

Worldwide Mobilization – Ready When You Are

NDT AND PWHT SOLUTIONS PVT LTD has the technical team, equipment, and offshore expertise to execute Pulse Eddy Current inspection projects globally. Whether on jackets, risers, FPSOs, or splash zone legs, our experienced professionals deliver safe, reliable, and data-driven inspection services tailored for challenging marine and offshore environments.

We are ready to mobilize on short notice for urgent or scheduled offshore inspection campaigns.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌍 Operating Worldwide

📧 support@solutionss.org

Pulse Eddy Current Inspection – Corrosion Under Insulation (CUI) – Ready to Deploy.