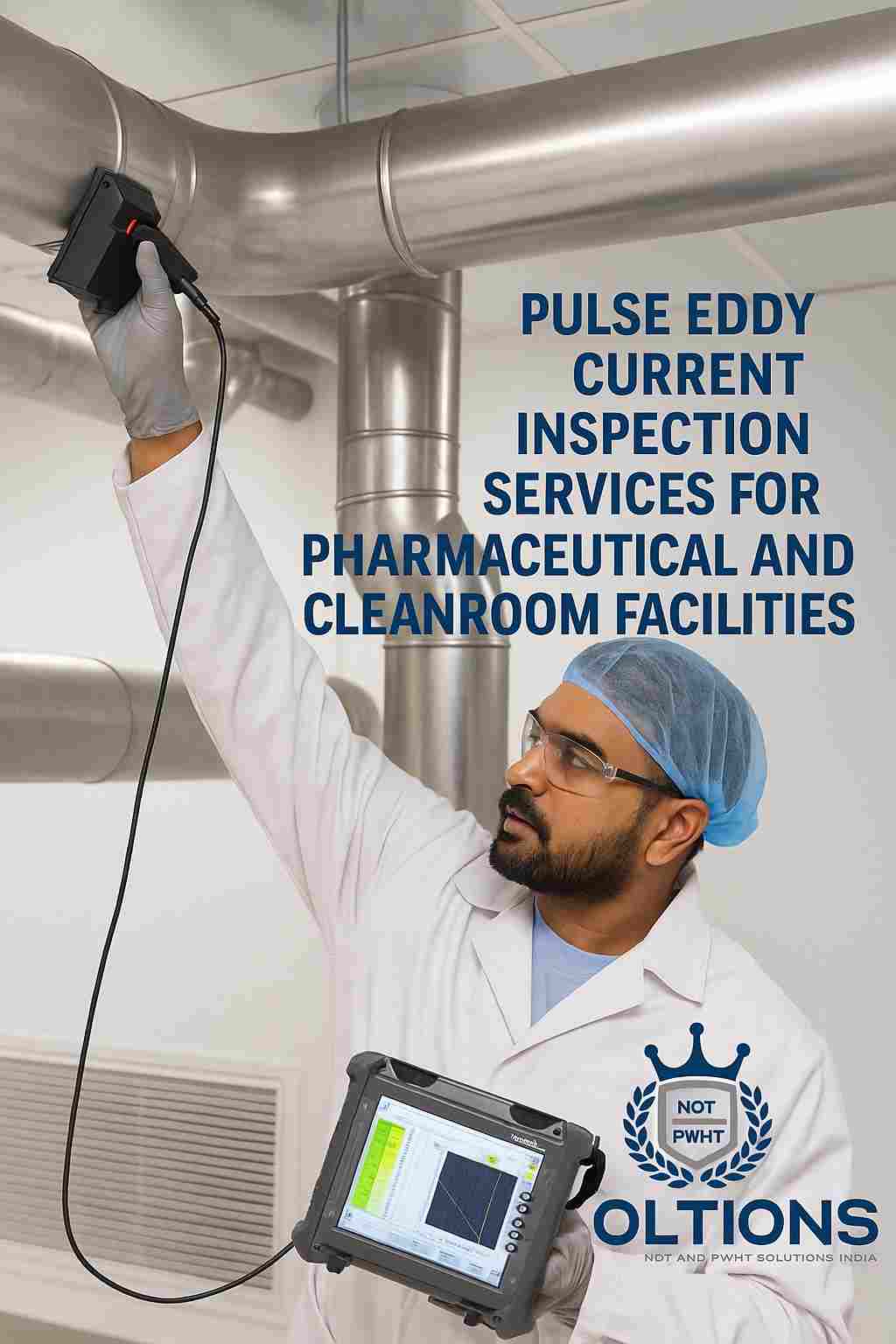

Pharmaceutical and Cleanroom Facilities

Pulse Eddy Current (PEC) Inspection Services for Pharmaceutical and Cleanroom Facilities by NDT AND PWHT SOLUTIONS PVT LTD. Clean, Non-Intrusive Corrosion Monitoring for Regulated Environments. Pharmaceutical and biotechnology facilities demand uncompromised hygiene, regulatory compliance, and zero disruption during inspections. Critical infrastructure such as insulated process piping, sterile HVAC systems, storage vessels, and cleanroom-grade utilities must maintain their structural integrity while preventing any contamination.

NDT AND PWHT SOLUTIONS PVT LTD offers Pulse Eddy Current (PEC) inspection services that are ideally suited for pharmaceutical and cleanroom environments, providing non-contact, through-insulation corrosion detection—without breaching sterile barriers or halting operations.

Why PEC for Pharmaceutical & Biotech Facilities?

Traditional inspection methods, such as Ultrasonic Testing (UT), typically require insulation removal, pipe access, and contact-based scanning—all of which are often prohibited in GMP-regulated, ISO-classified cleanrooms. PEC overcomes these limitations by enabling safe, sterile, and reliable wall thickness measurement through barriers, fireproofing, or coatings, without breaching seals or risking contamination.

Suitable Applications

Cleanroom HVAC ducting and structural supports

Insulated stainless steel process pipelines

Jacketed reactors and bioprocessing vessels

Utility tunnels, steam lines, and thermal systems

Coated steel structures in controlled zones

Key PEC Technology Advantages

Non-contact corrosion detection through insulation or cladding

No need to breach cleanroom seals or remove coatings

Sterile and contamination-free inspection method

Compatible with GMP, FDA, and ISO cleanroom standards

Enables rapid screening of inaccessible or critical zones

Benefits for Cleanroom & Pharma Operators

No shutdowns or insulation removal required

100% non-invasive and GMP-compliant

Reduces inspection time and manual handling

Ideal for predictive maintenance and compliance audits

Maintains cleanroom integrity and quality assurance

Global Readiness – Immediate Deployment

With specialized teams trained in regulated, sterile environments, NDT AND PWHT SOLUTIONS PVT LTD is equipped to mobilize PEC inspection services across India and globally. Our expertise spans pharmaceutical manufacturing plants, biotech laboratories, cleanroom infrastructure, and regulated utility zones—ensuring full regulatory compliance, minimal disruption, and reliable corrosion insights.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌐 Operating Worldwide

Pulse Eddy Current (PEC) Inspection Services for Pharmaceutical and Cleanroom Facilities – Ready to Deploy