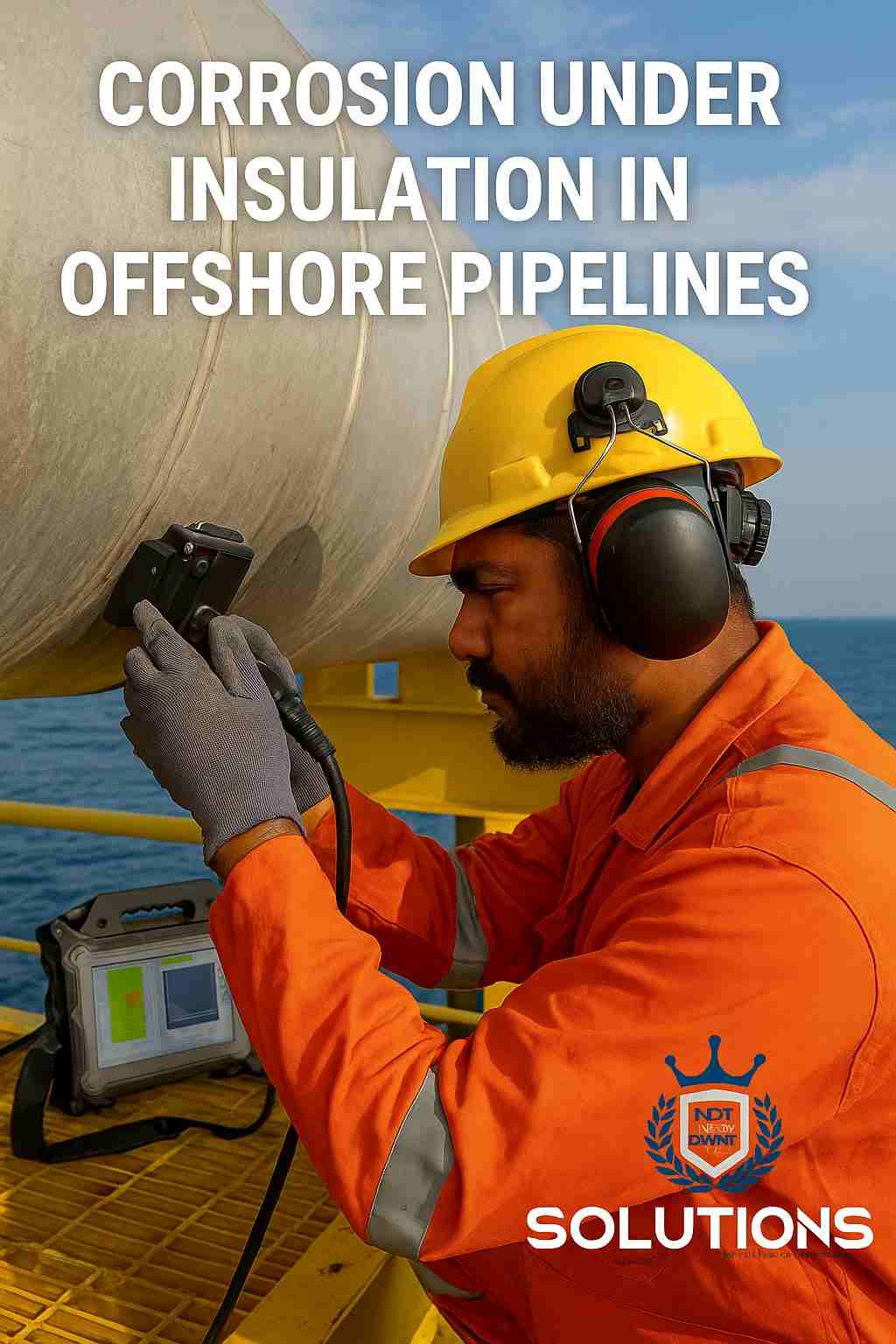

Corrosion Under Insulation (CUI)

Pulse Eddy Current (PEC) Inspection for Corrosion Under Insulation (CUI) by NDT AND PWHT SOLUTIONS PVT LTD – Global NDT Service Provider Pulse Eddy Current (PEC) is an advanced Non-Destructive Testing (NDT) technique designed to assess wall thickness and detect corrosion in carbon steel structures without the need to remove insulation, cladding, or fireproofing materials. It is particularly effective in identifying and quantifying Corrosion Under Insulation (CUI), a leading cause of unexpected failures in piping, vessels, and structural assets across various industries.

What is CUI and Why It Matters?

CUI is a hidden threat. It occurs when moisture seeps beneath insulation, initiating corrosion on the steel surface. Since it develops unseen, it can progress rapidly and compromise asset integrity, often without any visible signs. Traditional inspection methods require extensive insulation removal, causing downtime, labor overhead, and safety concerns.

With PEC, we detect wall loss through insulation layers, saving time, cost, and operational disruption. It’s a reliable solution for industries where insulation cannot be disturbed or where inspections must be performed while systems remain in service.

Applications of PEC for CUI Detection:

Insulated pipelines and process lines

Storage tank shells, roofs, and skirts

Pressure vessels and column bases

Pipe clamps, touchpoints, elbows, and dead legs

Offshore platforms, risers, and fireproofed steel structures.

Technical Highlights:

Material Compatibility: Ferromagnetic materials (carbon steel)

Inspection Through: Insulation, aluminum cladding, fireproofing (up to 200 mm)

Temperature Range: Up to 500°C — supports hot-service inspections

Data Output: Remaining wall thickness estimation

Limitations: Not suitable for stainless steel or detecting fine pitting/cracks.

Why Choose PEC for Your CUI Inspection:

Non-intrusive – No need to strip insulation

In-service capability – No production shutdowns

Rapid scanning – Ideal for screening large areas

Safe & efficient – Minimal access required

Cost-effective – Reduces manpower, access, and repair costs

Reliable insights – Supports RBI, inspection planning & lifecycle extension.

Global Service Capability:

At NDT AND PWHT SOLUTIONS PVT LTD, we offer cutting-edge PEC inspection services as part of our specialized integrity solutions. Headquartered in India and operating globally, we bring deep expertise, advanced technology, and a highly skilled team to deliver fast, safe, and accurate CUI detection across all industrial environments.

Whether it’s oil & gas, petrochemical, marine, power, or infrastructure, we’re ready to support your corrosion management strategy with world-class service and rapid mobilization.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌍 Operating Worldwide

📧 support@solutionss.org

Pulse Eddy Current (PEC) Inspection for Pipe Supports and Touch Points – Ready to Deploy.