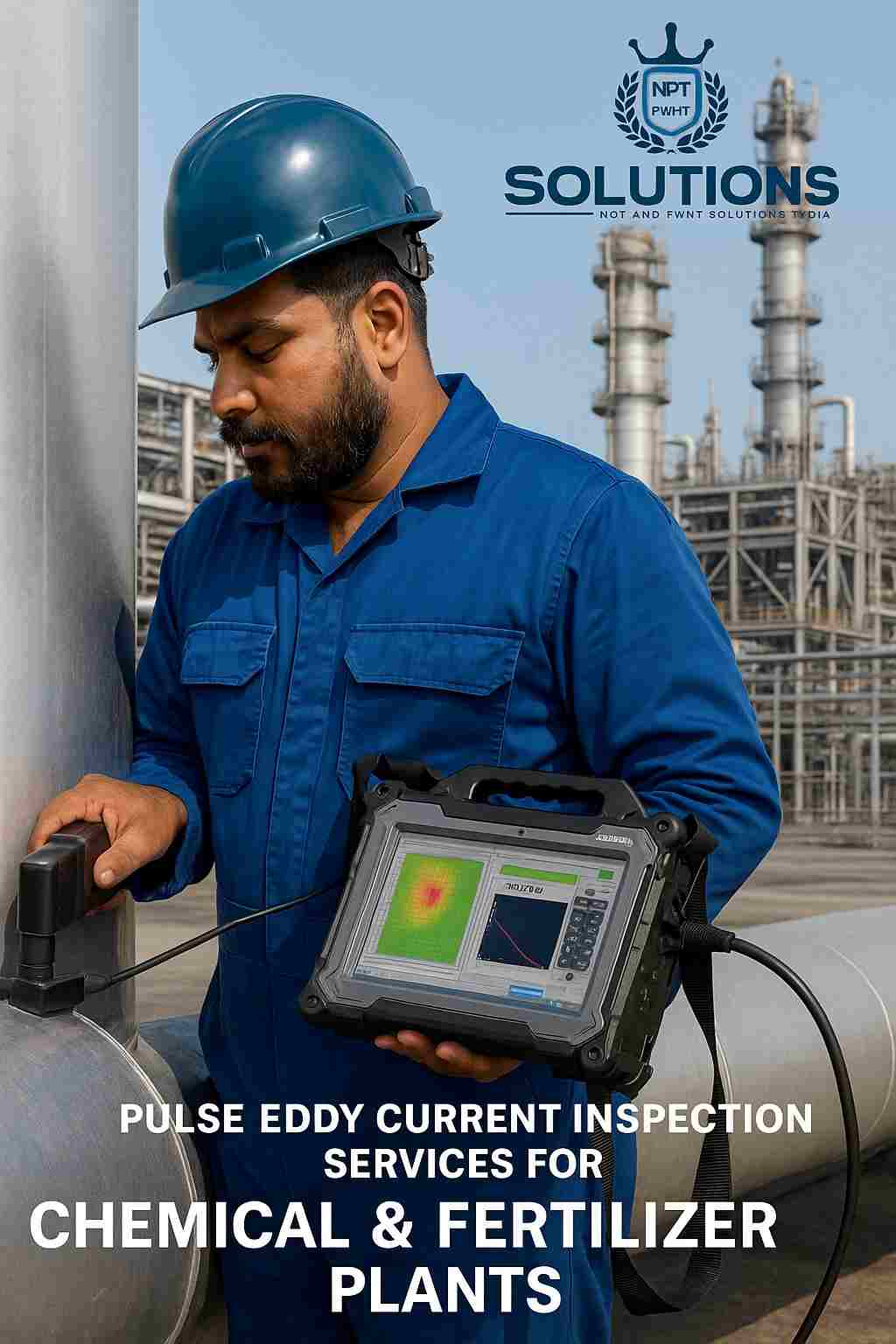

Chemical & Fertilizer Plants

Pulse Eddy Current (PEC) Inspection Services FOR Chemical & Fertilizer Plants by NDT AND PWHT SOLUTIONS PVT LTD. Reliable Corrosion Monitoring in High-Risk Process Environments Chemical and fertilizer plants involve high-pressure, high-temperature, and chemically aggressive processes. Critical assets like process pipelines, reactors, heat exchangers, and storage vessels are often insulated or coated for safety and efficiency, but this also creates hidden risks of Corrosion Under Insulation (CUI) and wall thinning, which can lead to catastrophic failures if undetected.

At NDT AND PWHT SOLUTIONS PVT LTD, we offer Pulse Eddy Current (PEC) inspection services as a non-intrusive, accurate, and efficient solution for detecting corrosion and material loss, without removing insulation, coatings, or halting operations.

Why PEC for Chemical & Fertilizer Industries?

In chemical and fertilizer plants, traditional ultrasonic thickness (UT) inspections require insulation stripping and surface preparation—increasing risk, downtime, and costs. PEC enables rapid screening through insulation, fireproofing, and coatings, making it ideal for hazardous, flammable, or corrosive zones where access is limited and safety is paramount.

Ideal Applications

Ammonia and urea plant piping systems

Acid and chemical transfer lines

High-pressure steam and process lines

Fireproofed structural steel columns

Storage tanks for fertilizers and chemicals

Heat exchangers and insulated reactors

Key PEC Features

Wall thickness measurement through up to 150mm of insulation

No insulation removal or surface cleaning needed

Safe for use in flammable or high-risk zones

High-speed data collection over large surface areas

Compatible with robotic access or scaffolding tools

Industry-Specific Advantages

Enhances predictive maintenance and asset integrity

Reduces inspection-related downtime and safety risk

Compliant with RBI (Risk-Based Inspection) methodologies

Ideal for aging infrastructure and compliance-driven audits

Supports long-term life extension planning

Global Service – Immediate Mobilization

NDT AND PWHT SOLUTIONS PVT LTD is equipped to deploy PEC inspection services globally—serving fertilizer complexes, petrochemical hubs, and industrial zones across Asia, the Middle East, Africa, and Latin America. Our experts ensure minimal disruption, maximum safety, and actionable insights.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌐 Operating Worldwide

Pulse Eddy Current (PEC) Inspection Services for Chemical & Fertilizer Plants – Ready to Deploy