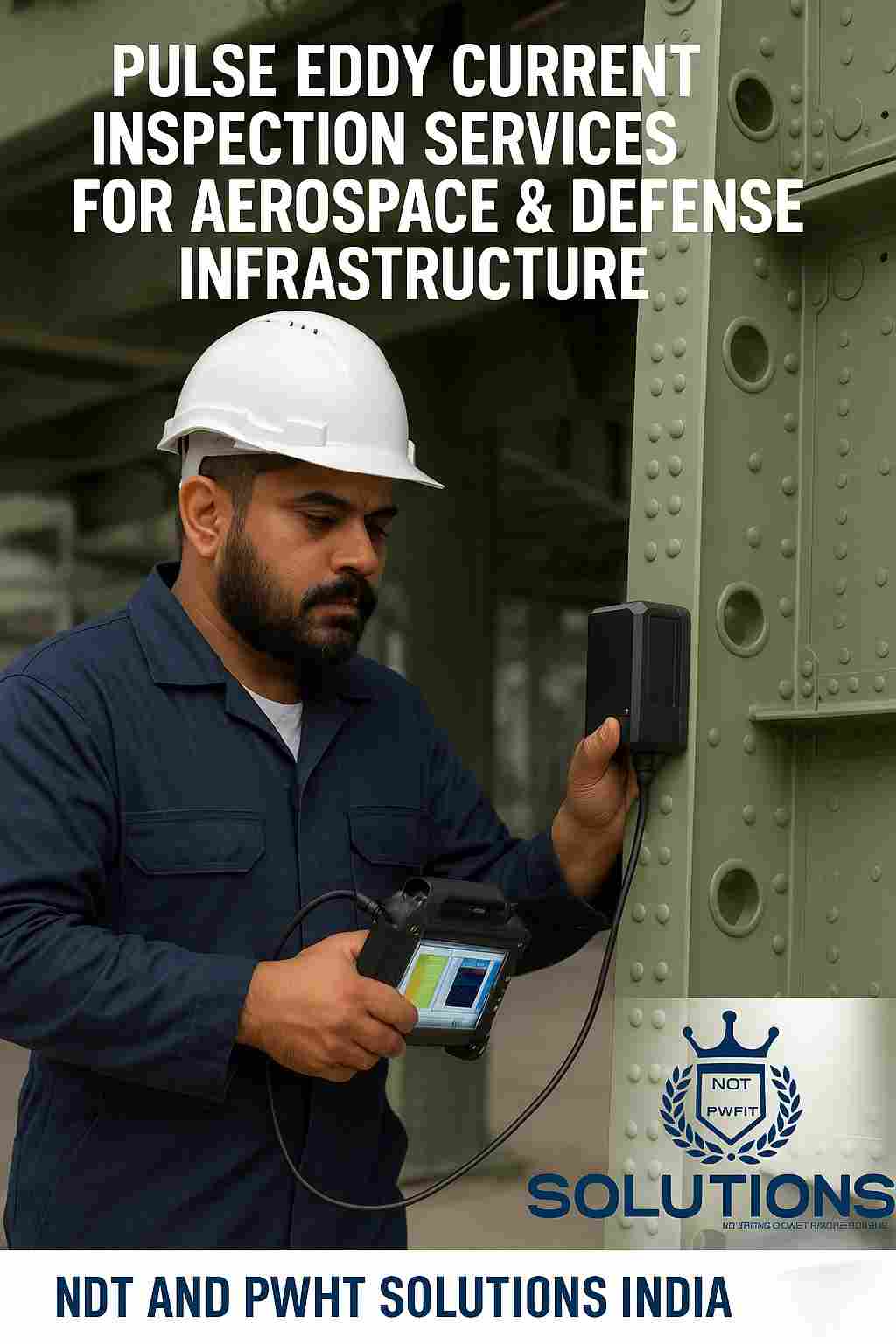

Aerospace & Defense Infrastructure

Pulse Eddy Current (PEC) Inspection Services for Aerospace & Defense Infrastructure Powered by NDT AND PWHT SOLUTIONS PVT LTD Precision Corrosion Monitoring for Mission-Critical Assets Aerospace and defense infrastructure—ranging from aircraft maintenance facilities and hangars to missile silos, radar towers, and military-grade pipelines—demands the highest level of integrity, reliability, and safety. Many of these assets are constructed with insulated, coated, or fireproofed materials, which can conceal dangerous levels of Corrosion Under Insulation (CUI) and wall loss.

NDT AND PWHT SOLUTIONS PVT LTD delivers Pulse Eddy Current (PEC) inspection services tailored for aerospace and defense environments, enabling non-intrusive, high-precision corrosion detection—without interrupting operations, removing insulation, or breaching secure zones.

Why PEC for Aerospace & Defense?

Traditional inspection methods usually involve insulation stripping, surface preparation, scaffolding, or special access permissions, which are often impractical or restricted in sensitive or classified zones. PEC technology overcomes these challenges by offering remote, fast, and reliable wall thickness measurements through coatings, fireproofing, and insulation, making it the ideal solution for time-sensitive and security-focused inspections.

Applicable Infrastructure

Aircraft hangars, radar station towers, and support structures

Aircraft fueling lines and thermal pipelines

Underground bunkers and fireproofed shelters

Structural steel components in naval and air force bases

Missile handling systems, silos, and pressurized systems.

PEC Technology Advantages

Wall thickness inspection through coatings, fireproofing & insulation

No surface prep or insulation removal required

Safe for confined, high-security, or flammable zones

Compatible with robotic or remote-access tools

Enables baseline and periodic monitoring for RBI programs.

Key Benefits for Defense Facilities

Minimizes disruption in active or classified areas

Improves asset longevity and mission readiness

Supports proactive maintenance & safety compliance

Ideal for remote, unmanned, or high-risk zones

Ensures infrastructure reliability under extreme conditions.

Trusted Global Service Partner

With the specialized capability to operate in restricted, offshore, and high-security environments, NDT AND PWHT SOLUTIONS PVT LTD offers PEC inspection services worldwide. We support aerospace agencies, defense contractors, and government operations across India, the Middle East, and allied territories, ensuring maximum safety and accurate integrity assessment under mission-critical conditions.

Contact Us – Your Global Integrity Partner

NDT AND PWHT SOLUTIONS PVT LTD

📍 Based in India | 🌐 Operating Worldwide

Pulse Eddy Current (PEC) Inspection Services for Aerospace & Defense Infrastructure – Ready to Deploy.